Easy Access to

Pressure Vessels

Parr reactors and pres-

sure vessels are equipped

with a unique

split-ring cover

clamp which adds greatly to the

convenience of the equipment

and the ease with which it can

be handled. This is an exclusive

Parr design (see sidebar) which

allows easy access to a pressure

vessel without using a heavy

screw cap, cumbersome cover

clamps, or a wide flange for

moveable bolts. Instead, the

head is clamped to the cylinder

by either a Type 4140 steel or

a Type 316 Stainless Steel ring

which has been split into two

sections. These sections slide

into place from the sides without

interfering with any fittings

attached to the head.

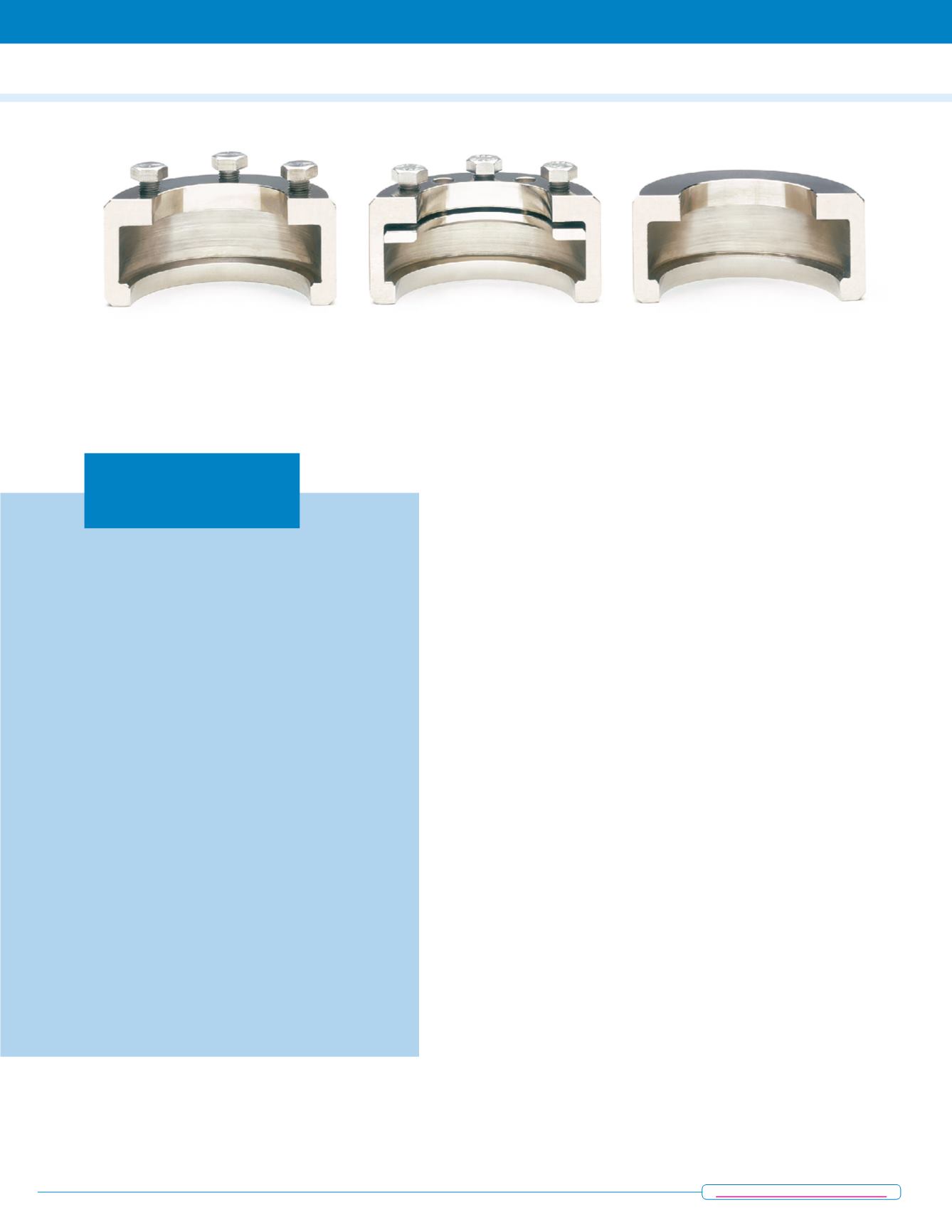

Self-Sealing and

Cap Screw Designs

Parr split-ring cover clamps

are made in two styles. For

reactors and vessels in which a

self-sealing O-ring is used as the

main head seal, there are no cap

screws in the split-ring sections.

The vessel is closed by simply

sliding the two ring sections

into place and locking them with

either an encircling drop band

or with attached, quick-opening

latches. This convenient closure

can be used on most small and

mid-sized stirred reactors and

pressure vessels, provided the

intended operating temperature

does not exceed the allowable

working temperature limit for the

O-ring seal.

Split ring closures for reactors

with PTFE, flexible graphite,

metal or other contained, flat

gaskets have a set of cap screws

in the rings which must be tight-

ened to develop the compressive

force required to seal the gasket.

These split rings are locked

together with either a drop band,

special compression ring with a

retaining lip, or quick opening

latches.

With either style, the closure

parts come completely away

from the vessel so that the head

with all of its fittings can be lifted

from the cylinder or the cylinder

can be dropped away without

disrupting any attached fittings.

When cap screws are used, they

are simply tightened or loos-

ened, they are never completely

removed from the split ring or

drop band. This saves time both

in opening and closing the vessel

and in looking for lost parts.

We have all heard the story of the man who

resigned from the Patent Office around 1900

because he believed that everything that could

be invented already had been. That is not the

philosophy that has driven Parr Instrument

Company over its more than a century of

service to the chemical industry. The following

prediction first appeared in February 1930 in the

“Forward” of our bulletin describing our catalytic

hydrogenation apparatus.

“The greatest chemical discoveries are yet

to be made, untold numbers of which will result

from the new studies in catalysis and catalytic

reactors. These studies have already unearthed

a mine of information, but with a more exact

knowledge of catalytic processes, much more

will be learned in the future.”

We are delighted with the foresight of our

predecessors here at Parr and are dedicated

to continuing this outlook for the future as we

conduct our second century of service to our

friends and customers in this critical industry.

Split-Ring

U.S. Patent No.

2625296

Split-Ring with Cap Screws

for Moveable Vessels

Split-Ring with Cap Screws

for Fixed Head Vessels

Split-Ring for Self Sealing

O-ring Closures

16

P a r r I n s t r u m e n t C o m p a n y

Split Ring Closures