27

P a r r I n s t r u m e n t C o m p a n y

1 - 8 0 0 - 8 7 2 - 7 7 2 0

2

S t i r r e d R e a c t o r s

higher coupling torque and more powerful motors are

available for higher viscosity applications.

Also, many reactors require a lower support bracket to

stabilize the stirring shaft. In applications with abrasive

particles or heavy mixing, a “footless” magnetic drive

with a larger diameter shaft may be provided.

5. Cooling Coil

An internal cooling coil can be installed in all reactors

(except the Micro sizes) to remove the heat of a reaction

and/or to cool the vessel at the end of a run. In some

reactors a cooling coil is furnished as a standard fitting.

In others, a coil can be added as an option in either

serpentine style or alternately in a spiral style for selected

models. For the micro sizes, with their limited dimen-

sions, a cold finger may be added as an option

6. Gage and Rupture Disc Ranges

The pressure gage range must be selected to pro-

vide the resolution desired, while having a range high

enough to handle the maximum pressure the reactor will

undergo. One would be tempted to simply get a gage

with the largest range possible, but this can reduce the

resolution to unacceptable levels. One good rule of thumb

for good resolution is to operate with the gage at half of

its maximum range.

The rupture disc is most commonly matched to the

Maximum Allowable Working Pressure of the vessel,

ensuring the disc will burst before reaching a pressure

beyond the MAWP range. Care must be taken not to

take the vessel above 90% of its burst pressure under

normal operation. This will help protect the disc from the

effects of repeated pressure cycles.

7. Controller Options

Parr controllers are typically set up to control tem-

perature, but may also be set up with digital pressure

displays, stirring speed, secondary temperature, and

other displays and controls.

These may be set up with data logging via PC as

well. For more information on these options,

8. Certification

ASME, CE, CHINA, and Parr Certifications are available

for users who require these recognized quality assurance

certifications.

9. Custom Options

A wide range of custom options such as special

openings in the head or cylinder, high viscosity stirrers,

windows, special valves, heaters or jackets, explosion

proof wiring, and volume modifications are available.

Various accessories, such as glass or PTFE liners,

condensers, catalyst holders, and alternate stirrers are

available to further adapt these reactors to the individual

user’s applications.

Detailed information for these and other options are

in

of

this catalog.

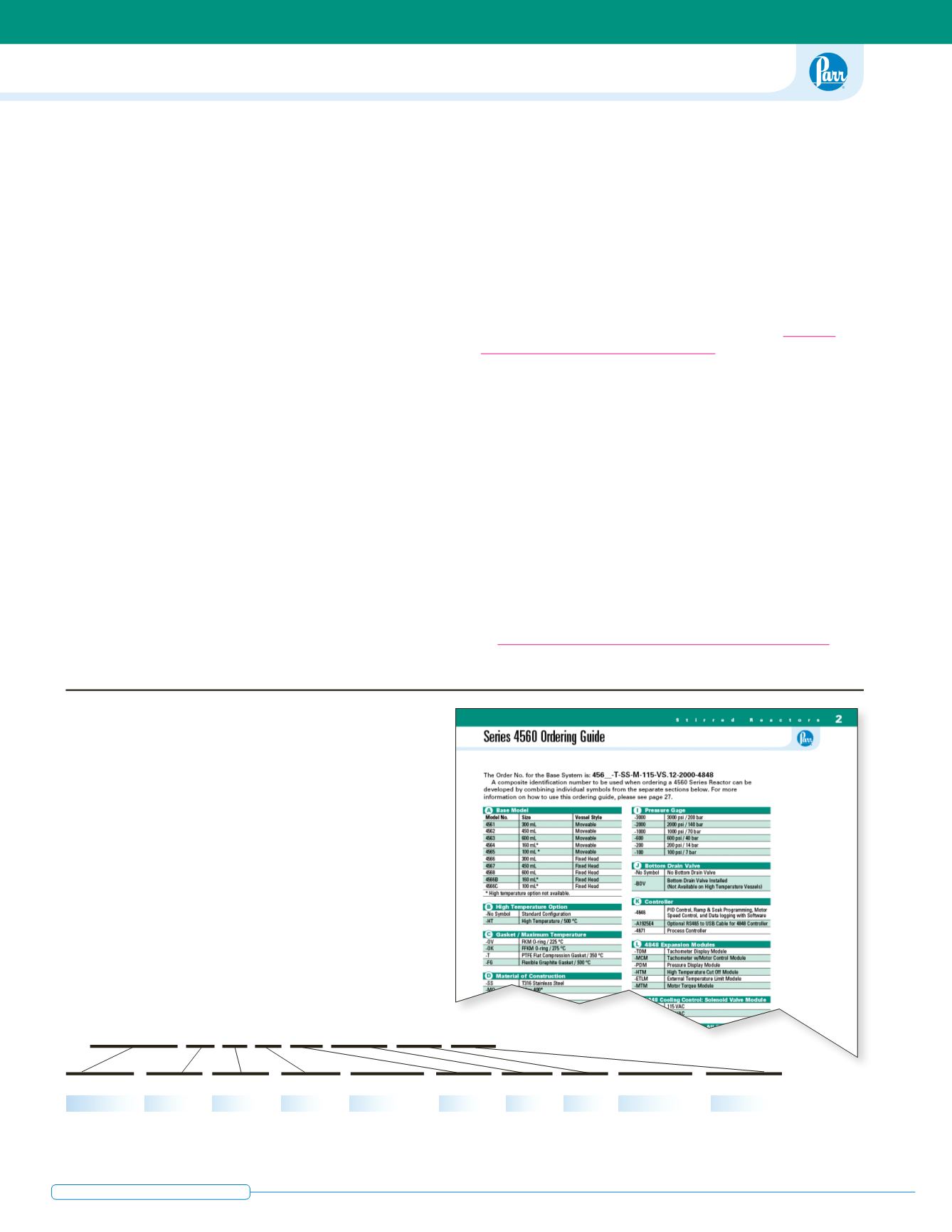

How to use the Ordering Guide:

A.

B.

C.

D.

E.

F.

G.

H.

I.

J.

Model

Gasket Material Stirrer Drive MOC Voltage Motor Gage BDV

Controller

No. 4568 -OV

-SS

-GP

-No Symbol -115

-XP.25 -3000 -No Symbol

-4848

No. 4568- OV-SS-GP-115-XP.25-3000-4848

T

he last page of each Reactor Series in this chapter

is an Ordering Guide. A composite identification/

order number can be generated by combining the

individual symbols from the separate sections.

In the following example: Using the Ordering Guide

from the Series 4560 Stirred Reactors for our sample

order, we have chosen to order a 600 mL fixed head

reactor, FKM O-ring, the vessel manufactured out of

T316 Stainless Steel, a general purpose magnetic drive

also made of T316SS, 115V power supply, 1/4 hp

explosion-proof motor, 3000 psi pressure gage, no

bottom drain valve, and a 4848 controller.

The order number for that particular configuration

would appear as follows: