60

P a r r I n s t r u m e n t C o m p a n y

Series Number:

5100

Type:

Glass or Metal

Bench Top

Vessel:

Fixed Head

Sizes, mL:

160 mL - 1.5 L

Maximum Operating

Pressure, psi (bar):

Glass:

150 psi (10 bar)

Metal:

1000 psi (69 bar)

Maximum Operating

Temperature, °C:

225

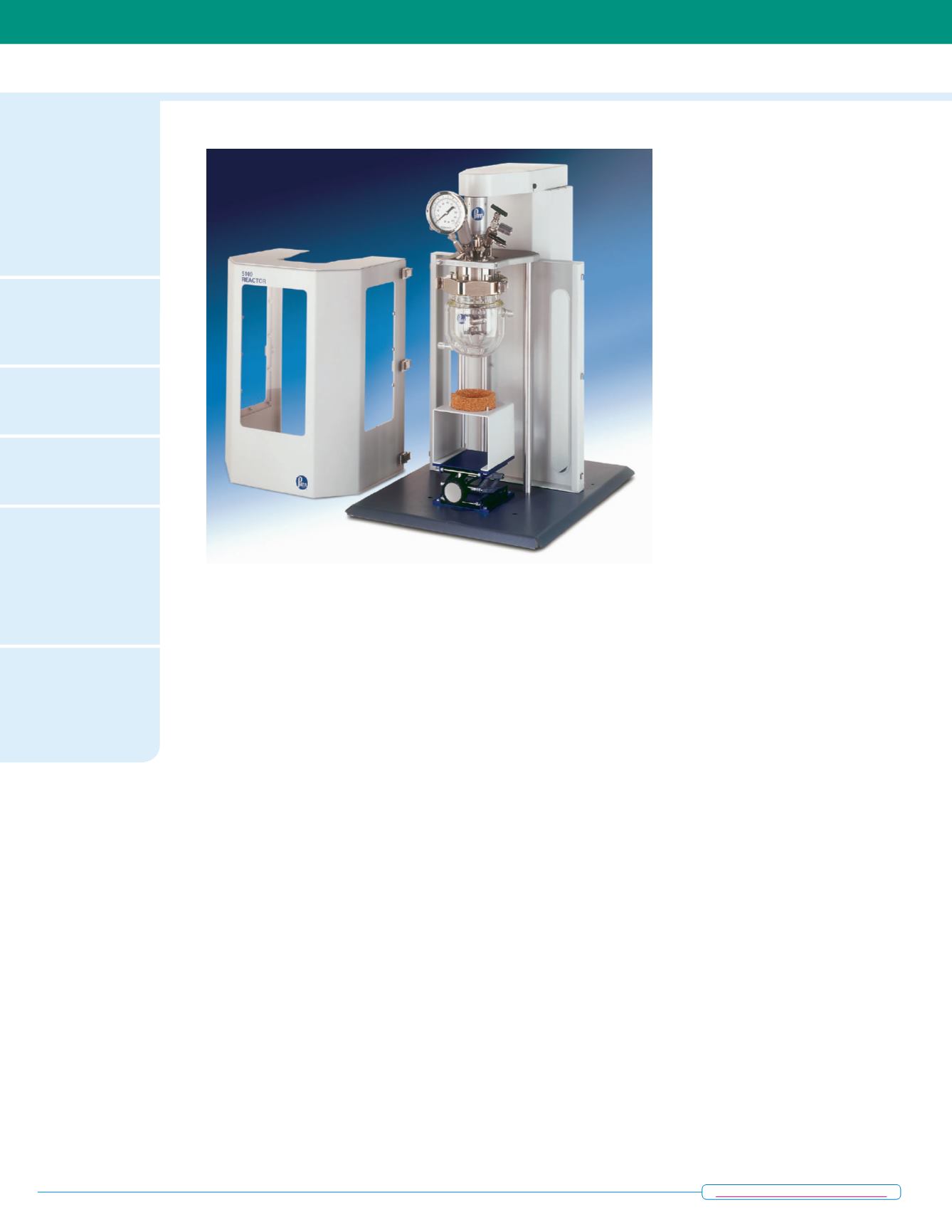

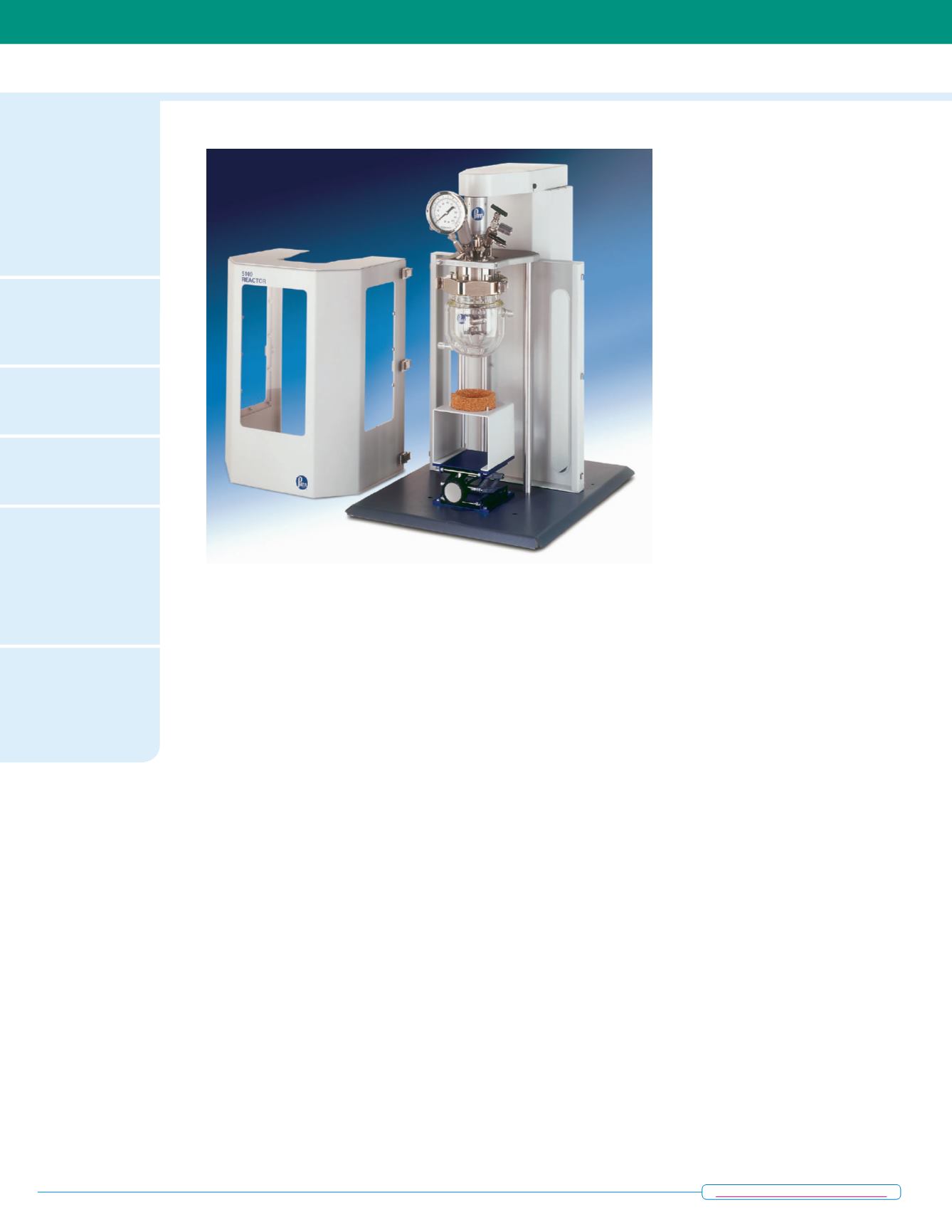

Series 5100 Low Pressure Reactors

T

he Parr series 5100 Low Pressure Reactors

are offered in response to users requests for:

1. A system for running reactions similar

to those that have been conducted for

many years in the Parr shaker, but which

offer stirring for better scalability, higher

operating temperatures and pressures,

and more extensive reactor controls and

instrumentation.

2. Reactors for elevated pressures with

glass vessels that permit direct observation

of mixing action, color changes, or changes

of state.

3. Reactors designed for convenient

operation at moderate pressure and/or for

corrosion resistance.

Convenient and Easy Sealing with O-rings

and Split Ring Closures

Parr has developed a new O-ring and closure

system to accommodate the requirements of this

unique glass-to-metal seal and support, which is

convenient to use. A face seal-type O-ring design

is used with the proven and popular Parr split

ring closure. For this application a special gasket

groove was designed to retain the O-ring on

the head of the reactor when it is opened. A full

range of O-ring materials is available for chemi-

cal compatibility with reactants, products and

solvents.

The split ring for the glass

vessel is padded with high

temperature plastic cushions so

the glass vessel does not come

in direct contact with the metal

split ring. Six sealing screws are

tightened only finger tight to

develop the seal on the O-ring.

The split ring snaps together

with latches to provide a secure

and positive closure.

The alternate metal cylin-

ders use a different split ring

designed to handle the higher

working pressure of the metal

vessels.

Positive Agitation by High

Torque Magnetic Drives

These reactors are equipped

with Parr magnetic drives to

provide a trouble free internal

stirrer. These drives have been

designed and tested to routinely

deliver 2000 hours of operation

without service.

Internal Stirrers

The standard internal stirrer for these vessels

is a turbine type impeller. These impellers have

been designed to provide good axial mixing to

keep any solid particles up in suspension and to

provide good gas distribution through the liquid

phase.

A gas entrainment impeller is available as an

alternate agitator for those users whose primary

need is gas re-circulation from the head space of

the reactor through the liquid phase.

Standard Reactor Fittings

The head of each glass reactor is equipped with:

• Pressure gage, 3-1/2 inch diameter, calibrated

0-200 psi and 0-14 bar

• Gas release valve

• Gas inlet valve

• Liquid sampling valve

• Internal thermocouple

• Internal cooling loop – standard 300 mL to 1.5 L

• Internal stirrer with magnetic drive

• Heads intended for use with glass cylinders

are equipped with spring-loaded relief valves

adjustable between 50-150 psi.

• All heads are equipped with a rupture disc

rated for 1000 psi.

• Internal fittings are T316 Stainless Steel with

PTFE coating.

5111 Bench Top Reactor, 1000 mL, Fixed Head, Glass Jacketed Vessel.