62

P a r r I n s t r u m e n t C o m p a n y

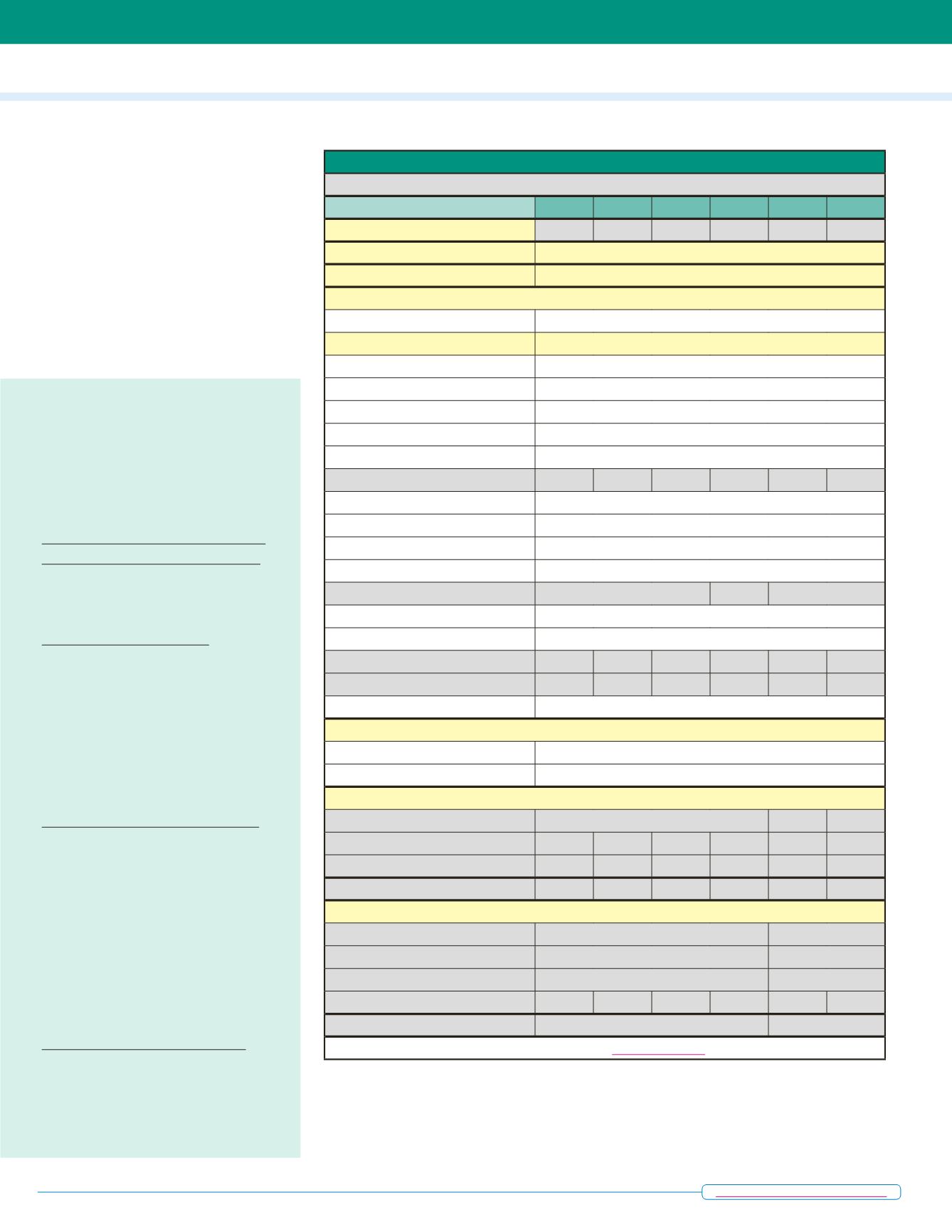

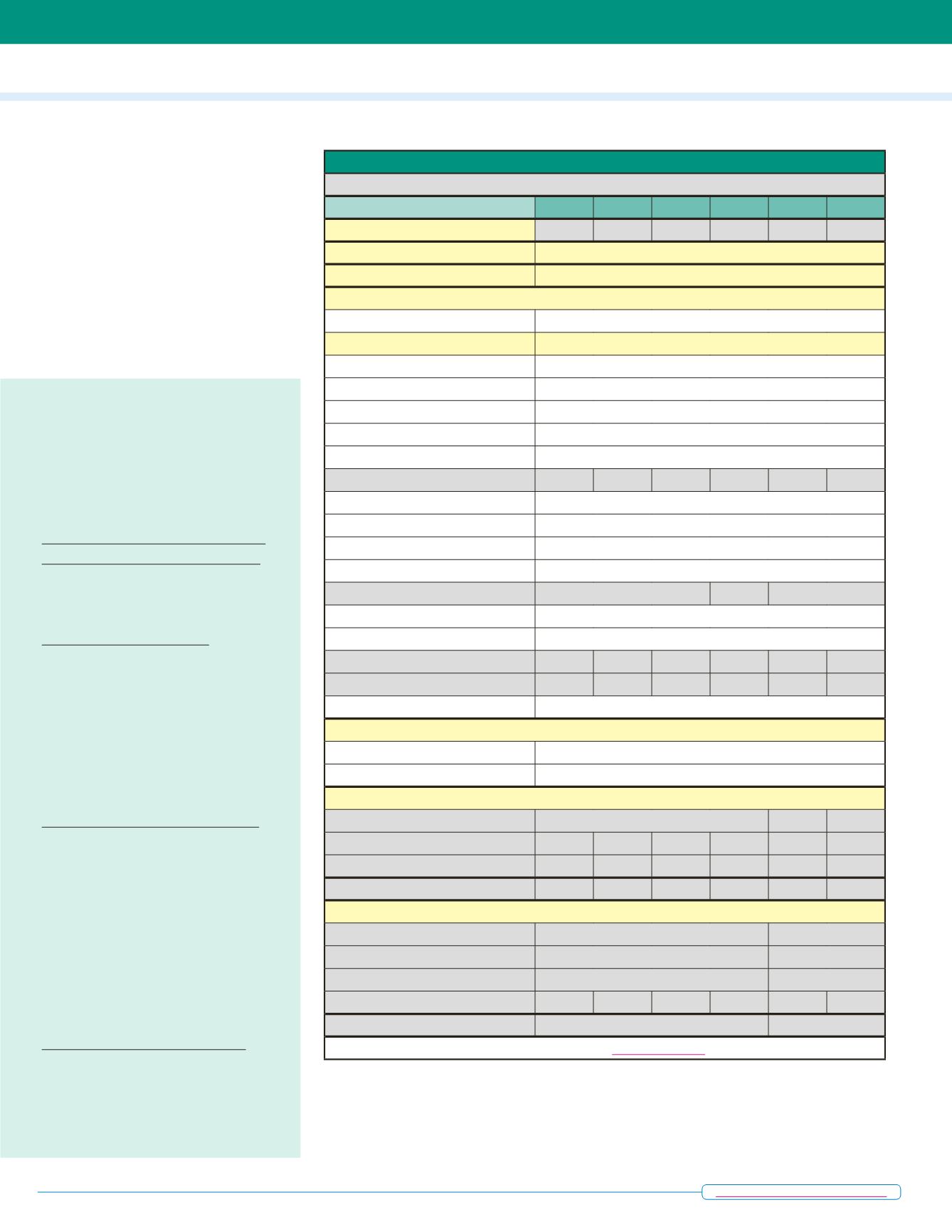

Series 5100 Low Pressure Reactors

Series 5100 Pressure Reactor System Specifications

Shaded bar indicates specifications that change within series.

Model Number

5101 5102 5103 5104 5111 5112

Sizes, mL

300

450

600

160

1000

1500

Maximum Pressure, Glass

150 psi (10 bar)

Maximum Pressure, Metal

1000 psi (69 bar)

Maximum Temperature

with FKM O-ring

225 °C

Vessel Style

Fixed Head

Reactor Mounting

Bench Top

Closure (Cap Screws)

Split-Rings (6)

Valve Connections

1/8" Male NPT

Magnetic Stirrer, Model No.

A1120HC9

Maximum Torque

16 Inch-Pounds

Impeller(s), 4-blade

1

2

2

1

2

2

Pressure Gage, Size

3.5 inches

Range, Glass

0-200 psi (0-14 bar)

Range, Metal

0-1000 psi (0-65 bar)

Temperature Measurement

Fixed, Type J, Thermocouple

Cooling Coil

Included

None

Included

Style

Single Loop

Heater Style

Mantle

Heater Power Glass, Watts

510

590

780

400

400

550

Heater Power Metal, Watts

510

590

780

400

450

650

Stirrer Motor

1/8 hp Variable Speed

Electrical Supply

Volts, AC

115 or 230

Maximum Load, amps, 115 / 230

8.5 / 5.2

Vessel Dimensions

Inside Diameter, inches

2.5

4

4

Inside Depth, inches

4.0

6.0

8.0

2.0

6.0

8.0

Weight of Cylinder, Glass, pounds

0.75

1.1

1.25

0.75

3

5

Weight of Cylinder, Metal, pounds

3

5

7

3

9

13

Reactor Dimensions

Width, inches w/o Controller

17

21

Depth, inches

24

26

Height, inches

30

33

Weight, pounds

60

63

66

60

109

113

Spare Parts Kit

5109M

5119M

Other options available. See Ordering Guide, visit

or call for more information.

Glass Under

Pressure

In the seventy years Parr has been offering

apparatus incorporating glass vessels and

bottles to be used under pressure, we have

learned the following important lessons.

1. Reactions at elevated pressures and

temperatures can be conducted safely only

if the user takes into consideration all of

the potential hazards that may occur if the

glass vessel should break under pressure.

2. Vessel design is important. Glass

vessels must have rounded sections,

proper annealing, cushioning supports,

and provisions for dealing with differential

thermal expansion as well as adequate

thicknesses, careful construction,

inspection and testing. All of the glass

vessels used in these reactors are tested

to a minimum of 225 psi (15 bar).

3. Careful maintenance is also critical to

safe operation of glass vessels. Scratches

on metal vessels which are highly

ductile are cosmetic. Scratches on brittle

glass vessels create enormous stress

risers which can completely destroy the

structural integrity of the vessel. Great

care must be employed in handling and

washing these vessels to maintain the

strength designed into them and confirmed

by their original hydrostatic testing.

4. Finally, operators must be trained to

recognize the potential hazards and ensure

that adequate safety provisions are in

place and operational at all times.

5110 Conversion Sets: Glass

to Metal or Metal to Glass

Series 5100 Reactors can

be easily converted between

glass and metal cylinders.

The conversion sets include

the cylinder, closure, gage and

safety relief devices for the

“converted to” system. Sets

do not include heater.