96

P a r r I n s t r u m e n t C o m p a n y

Output Modules:

The analog

outputs are 0-20 mA. A suitable

dropping resistor can be used

to convert this to 0-5 or 0-10

VDC. Analog outputs are com-

monly used to set stirrer motor

operating speeds, position

control valves, or drive mass

flow controllers or pumps.

Each analog output is capable

of controlling four separate

devices or functions.

The digital outputs are

open collector type capable of

sinking up to 300 mA . They

are commonly used to control

heaters, solenoid valves for

cooling or other flow control,

system safety shut down,

visual and/or audible alarms,

and similar devices. Each digi-

tal output module is capable

of controlling sixteen separate

devices or functions.

Control Loops

The controller can provide

any number of PID or ON/OFF

control loops, limited solely by

the available CPU memory.

The PID control algorithm

includes auto-tuning and fuzzy

logic overshoot suppression for

each control loop. For heating

and cooling control, the PID

control loops provide time

proportioning of the associated

digital output.

Many temperature control

applications utilize two sepa-

rate time proportioning ouputs

with one PID controller; one for

heating and one for cooling.

Control loops can be linked

together to provide cascade,

feed forward or ratio control

for difficult or advanced control applications.

Both high and low limit values can be entered

for each control loop to sound alarms or initiate

safety control schemes.

Set Point Programming

Recipes for controlling the entire process of a

reactor can be written using the setpoint profiler

incorporated into the control firmware. A single

profile may be from 2 to 50 segments in length.

A typical profile might be a ramp and soak

of the reactor temperature but, in addition, the

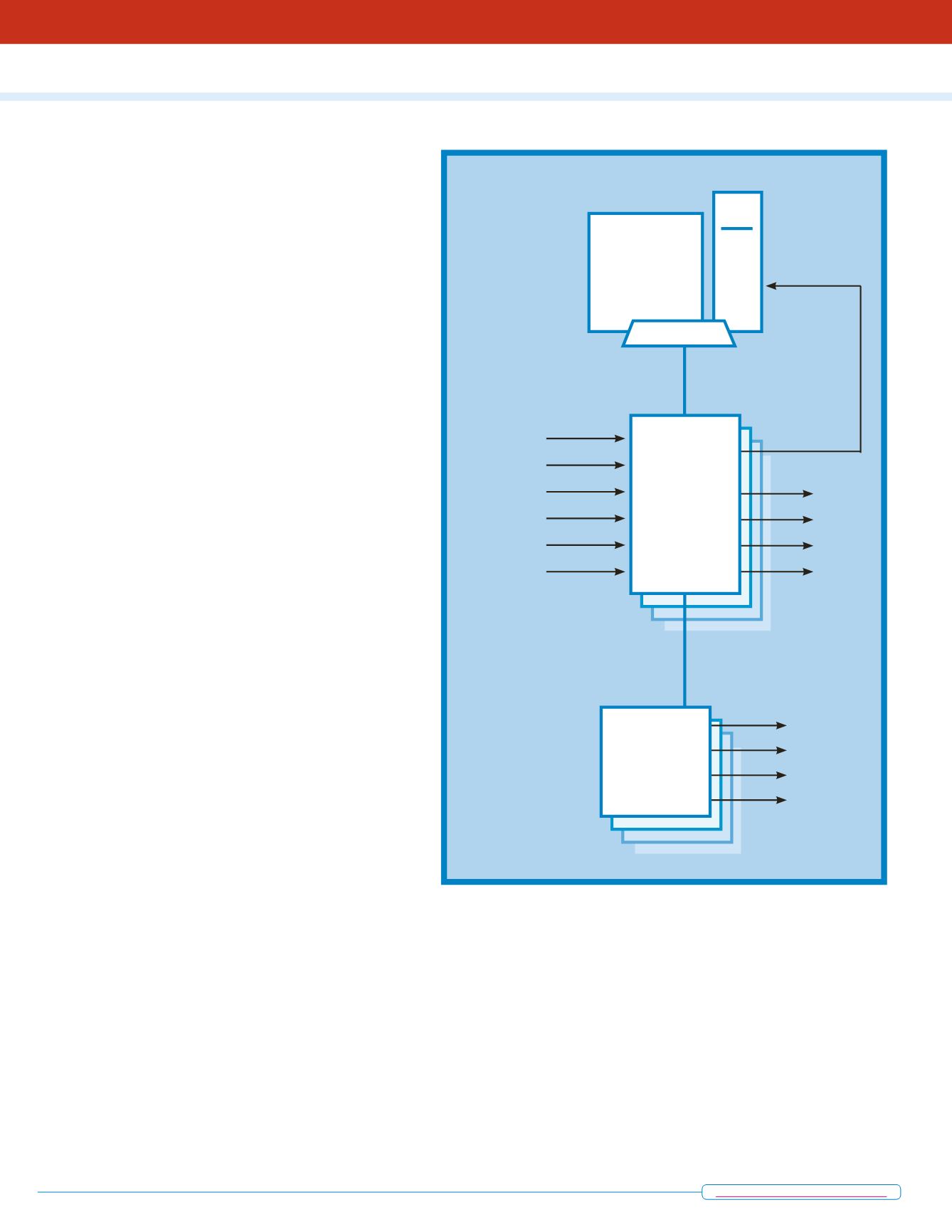

4871 Process Controller Input/Output Diagram.

Parr 4871

Process

Controller

Parr 4875

Power Controller

Data Logging

Alarms

Temperature

Pressure

Stirrer Speed

Flow Rate

Safety Links

Other

Heating Control

Cooling Control

Stirrer Control

Safety Interlock

PC Graphical

User Interface

Multiple 4875 Power Control Modules

can be controlled, with individually

isolated inputs and outputs, with one

4871 Process Controller.

Thirty-one 4871 Controllers can be

controlled by a single PC operating

the SpecView software.

4871 Process Controller

analog and digital outputs can be tied to the basic

profile to start and stop flows, activate stirrers

or accessories, or change alarms. Any of the set-

points within the profile can be protected with the

setpoint guarantee function that assures that the

process variable will be within the entered limits

before the profile can proceed.

The number of set point programmers is lim-

ited by the amount of available memory in

the controller CPU. Typically, at least eight

separate profiles can be running independently

(8 reactors each on their own program, for

example) simultaneously.