D i s b o n d i n g A p p a r a t u s f o r A S T M G 1 4 6

D i s b o n d i n g A p p a r a t u s f o r A S T M G 1 4 6

Bulletin CS35MB 0413

P

arr

I

nstrument

C

ompany

211 53rd Street • Moline, Illinois 61265 USA 1-309-762-7716 • 1-800-872-7720 • Fax: 1-309-762-9453

E-mail:

•

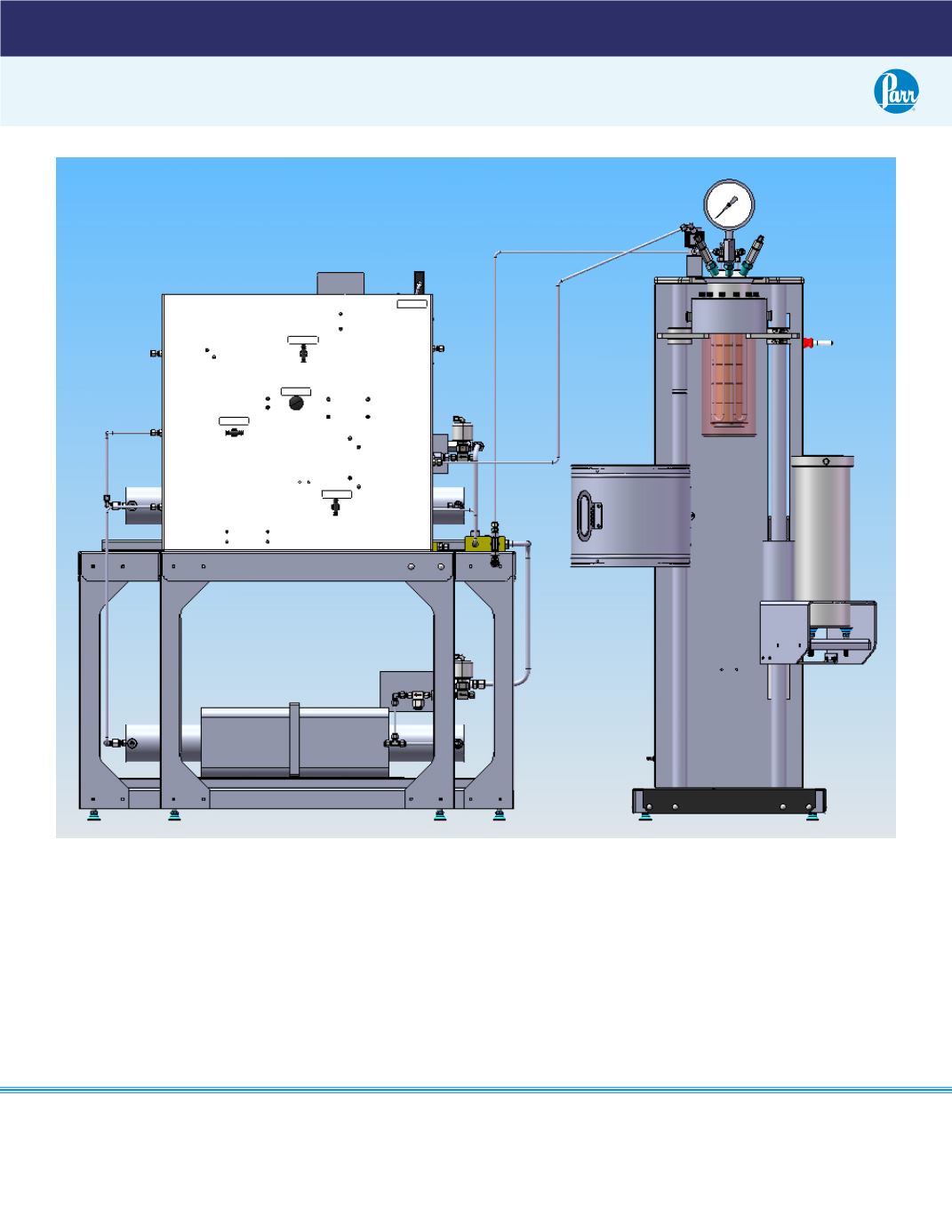

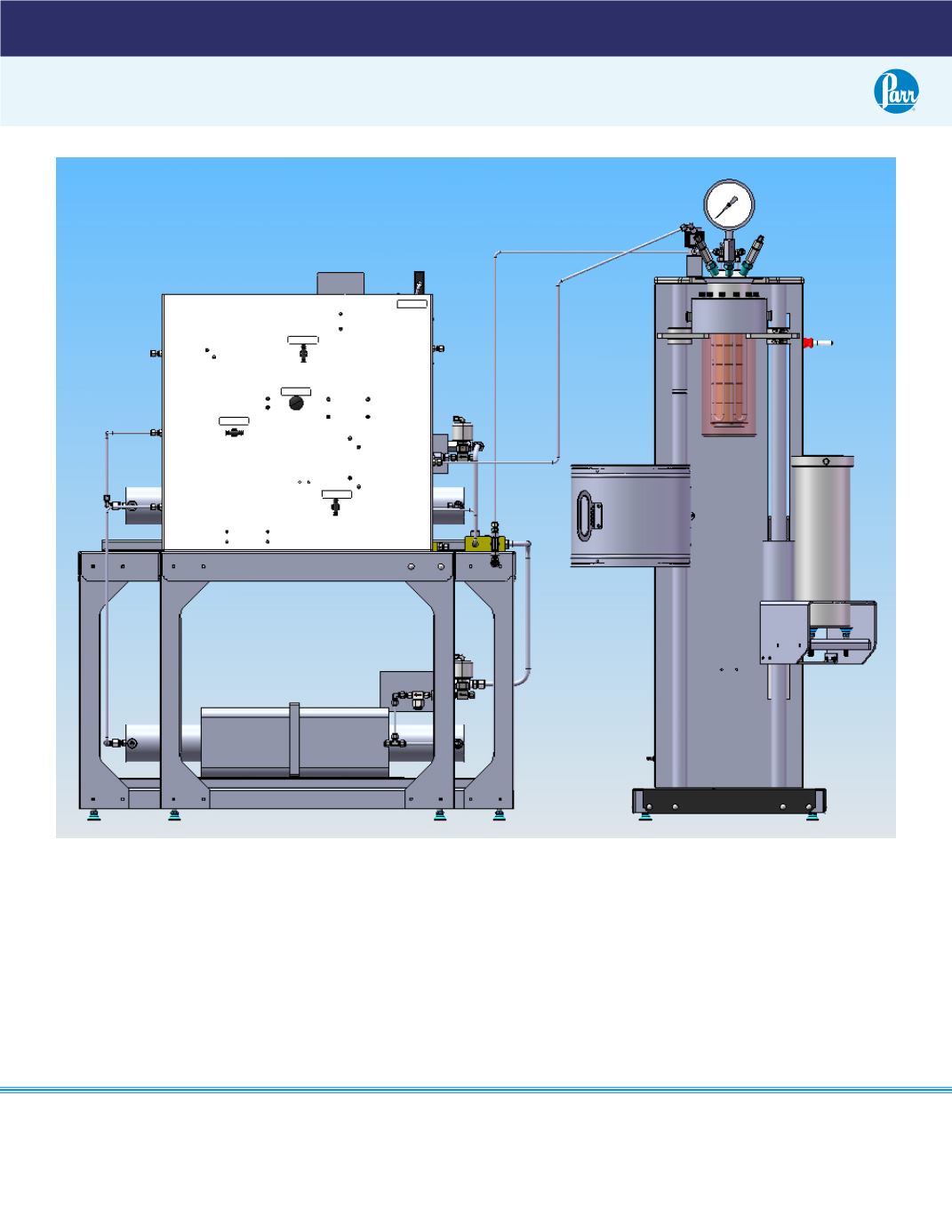

Disbonding Apparatus front view

The system incorporates an automated back pres-

sure regulator and a variety of automated valves for

pressure control.The control system (not pictured)

for the apparatus automatically purges the vessel

with argon, performs a high pressure leak test with

nitrogen and then sequences the main portion of

the test.The main test consists of filling the test

cell with hydrogen, heating the vessel at a user

defined temperature set point for a period of typi-

cally 48 hours. After this, the vessel is cooled at a

predefined rate, typically 150 °C/hr, until the inside

temperature reaches 200 °C.The test cell is then

automatically vented, purged and cooled further

so that the test samples can be safely retrieved. All

important test parameters are user adjustable.