73

P a r r I n s t r u m e n t C o m p a n y

1 - 8 0 0 - 8 7 2 - 7 7 2 0

3

S p e c i a l t y & C u s t o m R e a c t o r s

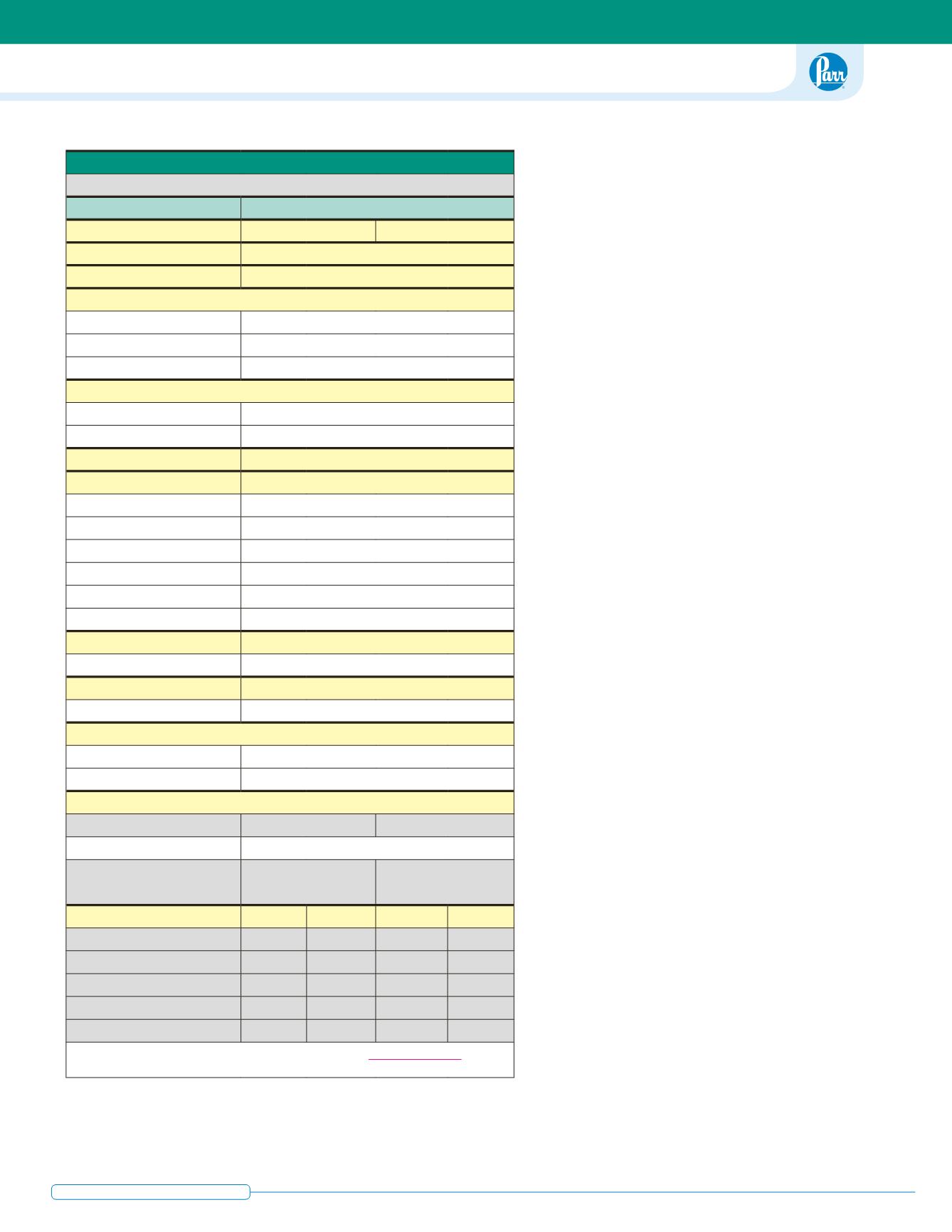

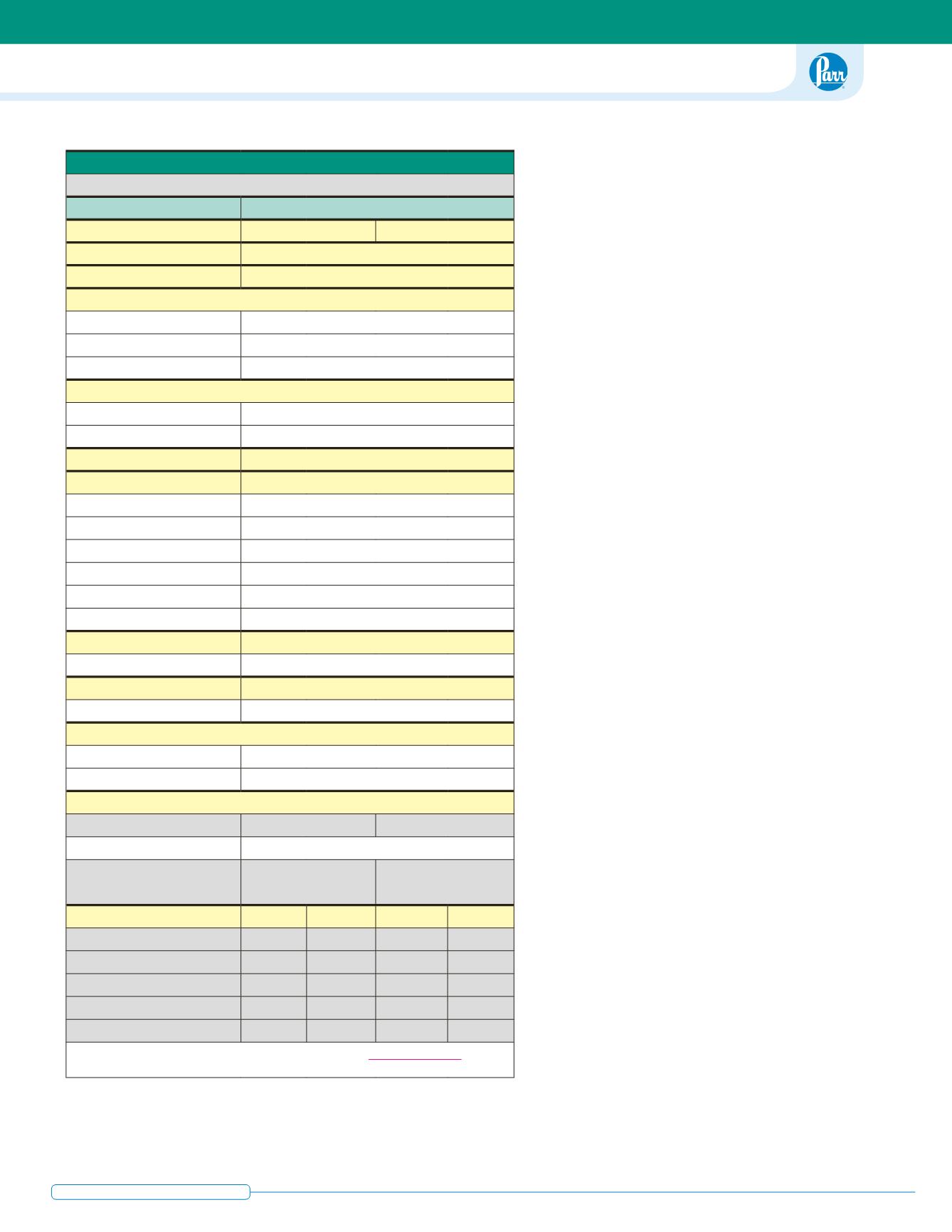

Series 5000 Pressure Reactor System Specifications

Shaded bar indicates specifications that change within series.

Model Number

5000

Sizes, mL

45

75

No. of Reaction Vessels

6

Maximum Pressure

3000 psi (200 bar)

Maximum Temperature

with FKM O-ring

225 °C

with FFKM O-ring

275 °C

with PTFE Flat Gasket

300 °C

Closure

with O-ring

Screw Cap

with Flat Gasket

Screw Cap (6 Cap Screws)

Material of Construction

T316SS

Process Controller

Model 4871

Analog Inputs

6 Temperature

6 Pressure

1 Motor Speed

Analog Outputs

1 Stirrer Speed (Optional)

Digital Outputs

6 PID Temperature Control

Temperature Measurement

6 Thermowells

Heater Style

6 Band Heaters, Aluminum Block

Heater Power Watts

250W Per Station, 1500W Total

Stirrer Motor Type

Manual or Computer Controlled

Stirrer Style

PTFE- or Glass- Coated Magnetic Stirrer Bar

Electrical Supply

Volts, AC

115 or 230

Maximum Load, amps

15 / 7.5

Vessel Dimensions

Inside Diameter, inches

1.2

1.5

Inside Depth, inches

2.69 Flat Gasket, 2.50 O-ring

Weight of Vessel, pounds

3

(w/ Panel-mounted valves)

6

(w/ Head-mounted Valves)

Dimensions

Width, in.

Depth, in.

Height, in.

Weight, lb.

Heater

25.75

9.25

2.875

31

Stirrer

28

9.5

7.625

12

4871 Controller

13

11

15

14

Manifold, Remote

26.5

9.0

15

36

Manifold, Head Mount

26.5

9.0

15

18

Other options available. See Ordering Guide, visit

,

or call for more information.

Operating Modes

The Series 5000 Multiple Reaction System

provides an apparatus for running up to six

reactions in parallel to build a database for com-

paring and optimizing operating conditions. The

user can design experiments to:

• Run all reactions at the same temperature

and pressure while varying catalyst loading

or reactant concentrations to optimize these

parameters.

• Run all reactors with identical loads varying

pressures at a common temperature to study

the effect of pressure on reaction rates.

• Run individual reactors with individual load-

ing and temperature and pressure to screen

multiple options for activity.

A comparison of the plots of pressure drop

versus time within the reactors running under

parallel conditions will usually be the most

useful means of measuring reaction rates and

comparing operating conditions. The internal

thermocouple also provides a means of detect-

ing temperature changes due to exothermic

reactions.

Reactor Options

As Parr customers have come to expect with

our line of laboratory pressure reactor equip-

ment, these reactors are offered with a number

of options which permit the user to configure

the system to their reactions and intended oper-

ating conditions. These options include:

O-ring or Flat Gasket Seals.

Vessels with

O-ring seals are closed by simply tightening the

screw cap down hand tight. The maximum oper-

ating temperature will depend upon the O-ring

material. When equipped with FKM (Viton

®

)

O-rings operating temperatures up to 225 °C

are permitted. By substituting FFKM (Kalrez

®

)

O-rings this limit can be raised to 275 °C. Careful

consideration of chemical compatibility must

also be given when selecting O-ring materials.

PTFE gaskets can be used to temperatures up

to 300 °C and offer virtually universal chemi-

cal compatibility. Six cap screws are used to

develop the sealing forces on the PTFE gaskets

in this design.