82

P a r r I n s t r u m e n t C o m p a n y

Fluidized Bed Reactors

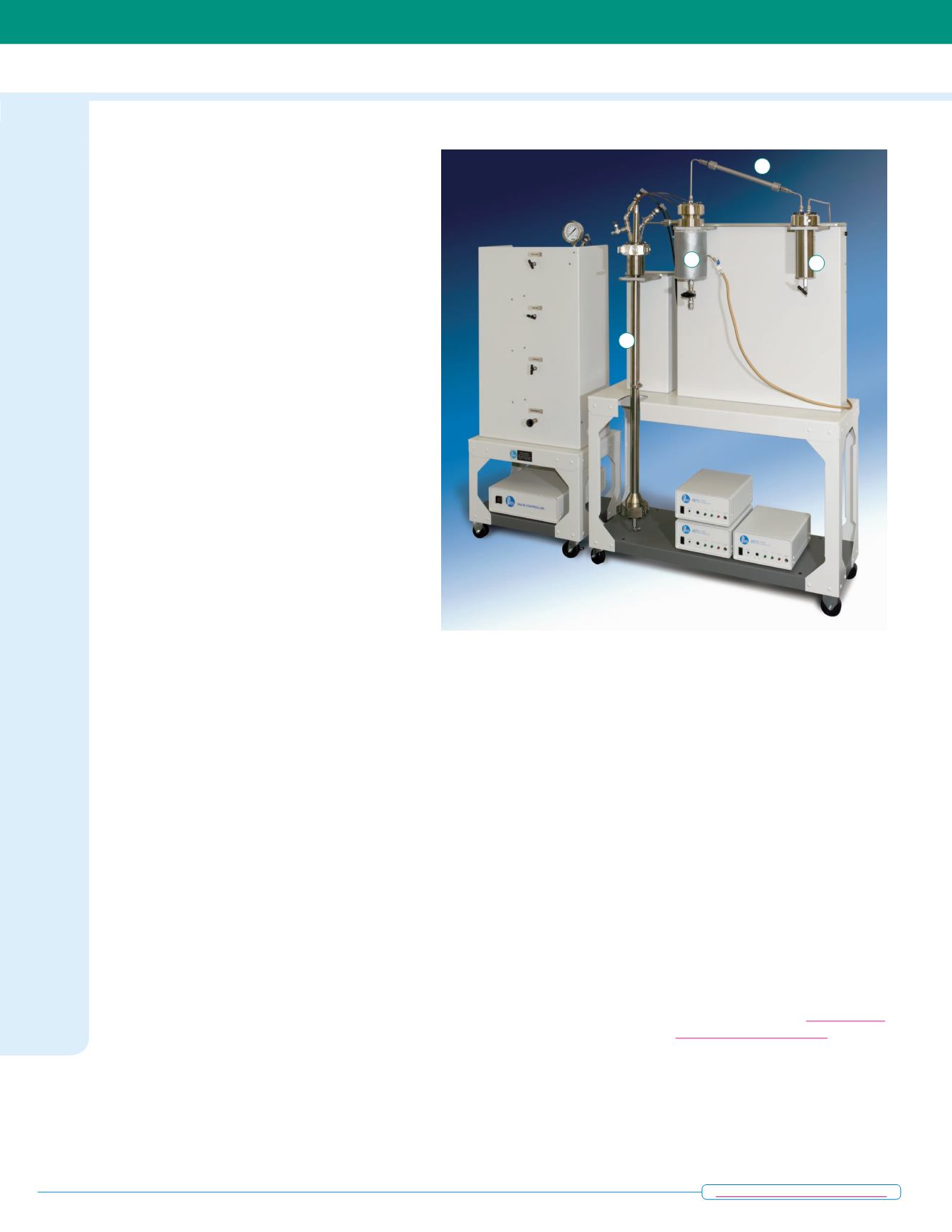

The reactor system pictured

on this page includes the fol-

lowing key components:

• A gas handling and mixing

sub-system used to blend and

regulate the flow of reactant

gas to the bottom of the

reactor.

• The reactor is roughly

one meter long with a 2.5 cm

ID. The lower portion of the

reactor incorporates an easily

replaced porous metal gas dif-

fusion plate and the top of the

reactor widens abruptly to form

a disengaging zone for the

fluidized bed. Separate heaters

are provided for both the main

reactor and disengaging zone.

A multipoint thermocouple is

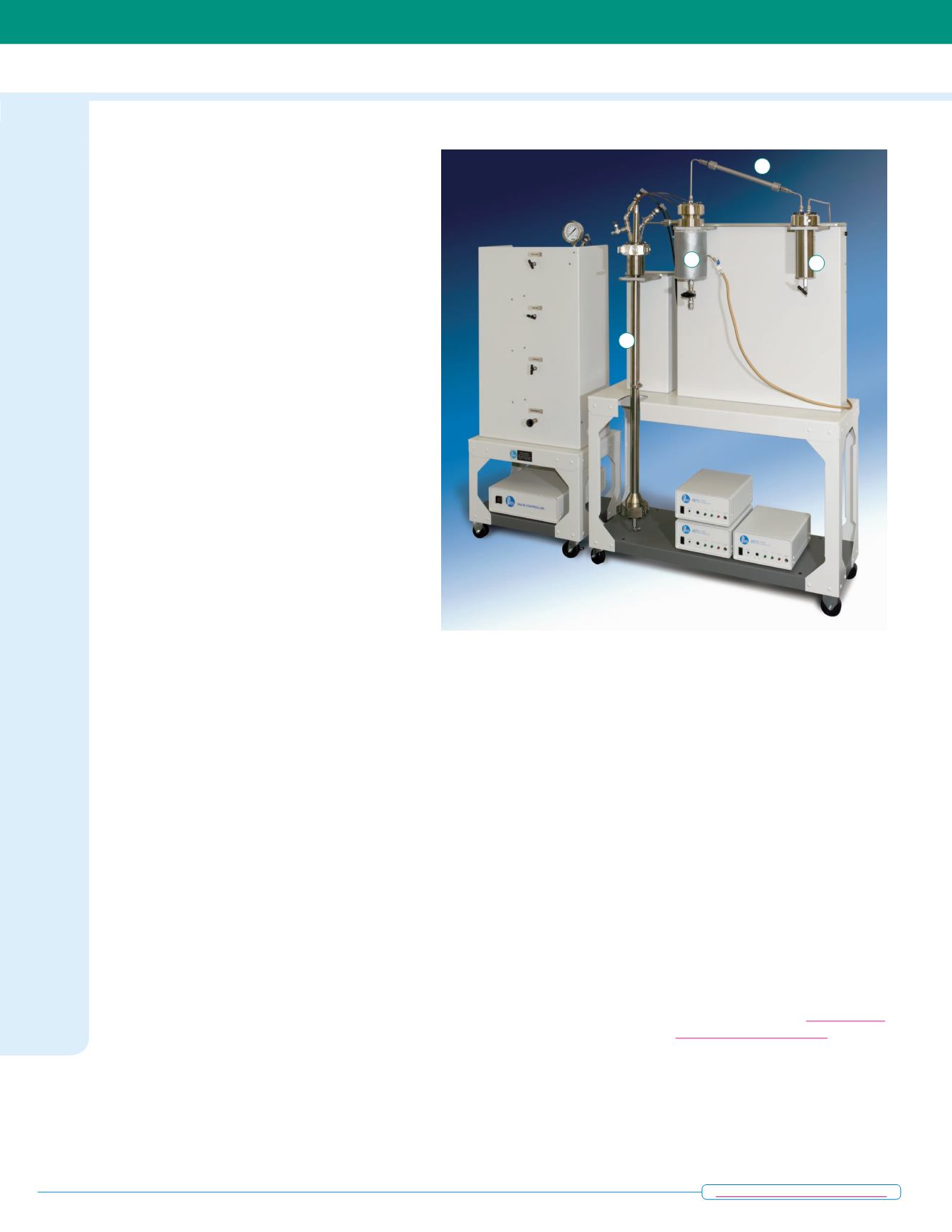

The Parr Fluidized Bed Reactor features the Reactor (A), a Heated Cyclone

Separator (B), a Cooling Condenser (C), and a 600 mL Product Receiver (D).

P

etroleum and Fluidized

Bed Reactors are used

extensively in the chemical

process industries. The distin-

guishing feature of a fluidized

bed reactor is that the solids

bed or catalytic particles are

supported by an up flow of

gas. This reactor provides

easy loading and removing of

catalyst. This is advantageous

when the solids bed must

be removed and replaced

frequently. A high conversion

with a large throughput is pos-

sible with this style of reactor.

Such reactors inherently pos-

sess excellent heat transfer and

mixing characteristics.

Fluidized beds have been

significantly utilized in chemical

processes, in which parameters

such as diffusion or heat

transfer are the major design

parameters. Compared to

packed bed, a fluidized bed has

notable advantages such as

better control of temperature,

no hot spot in the bed, uniform

catalyst distribution and longer

life of the catalyst. The desir-

ability of using fluidized beds is

dependent on achieving good

mixing between the solids and

the suspending fluid.

Nearly all the significant

commercial applications of flu-

idized bed technology concern

gas-solid systems. Applications

of fluidized bed reactors

include but are not limited to

Fisher-Tropsch synthesis, cata-

lytic cracking of hydrocarbons

and related high molecular

weight petroleum fractions.

Gasification in a fluidized bed

can be utilized to convert coal,

biomass and other waste mate-

rials into synthesis gas.

A

B

C

D

provided for monitoring the

internal reactor temperature

distribution.

• A heated cyclone separator

or filter is provided imme-

diately downstream of the

reactor to capture the fines

resulting from particle attrition.

• The reaction products are

then cooled by a condenser

and collected in a 600 mL prod-

uct receiver.

• The system pressure is

maintained by a dome loaded

back pressure regulator.

• All system functions and

parameters are monitored and

maintained by a Parr 4871

Process Controller

.