97

P a r r I n s t r u m e n t C o m p a n y

1 - 8 0 0 - 8 7 2 - 7 7 2 0

4

R e a c t o r C o n t r o l l e r s

While a maximum of 99 profiles can be stored in the controller

itself, an unlimited number can be stored in the operator’s PC for

rapid transfer to the controller.

In addition to the setpoint profiling capability, the controller is

also equipped with a setpoint scheduling function. This feature

can operate up to 8 profiles operating on a common time base.

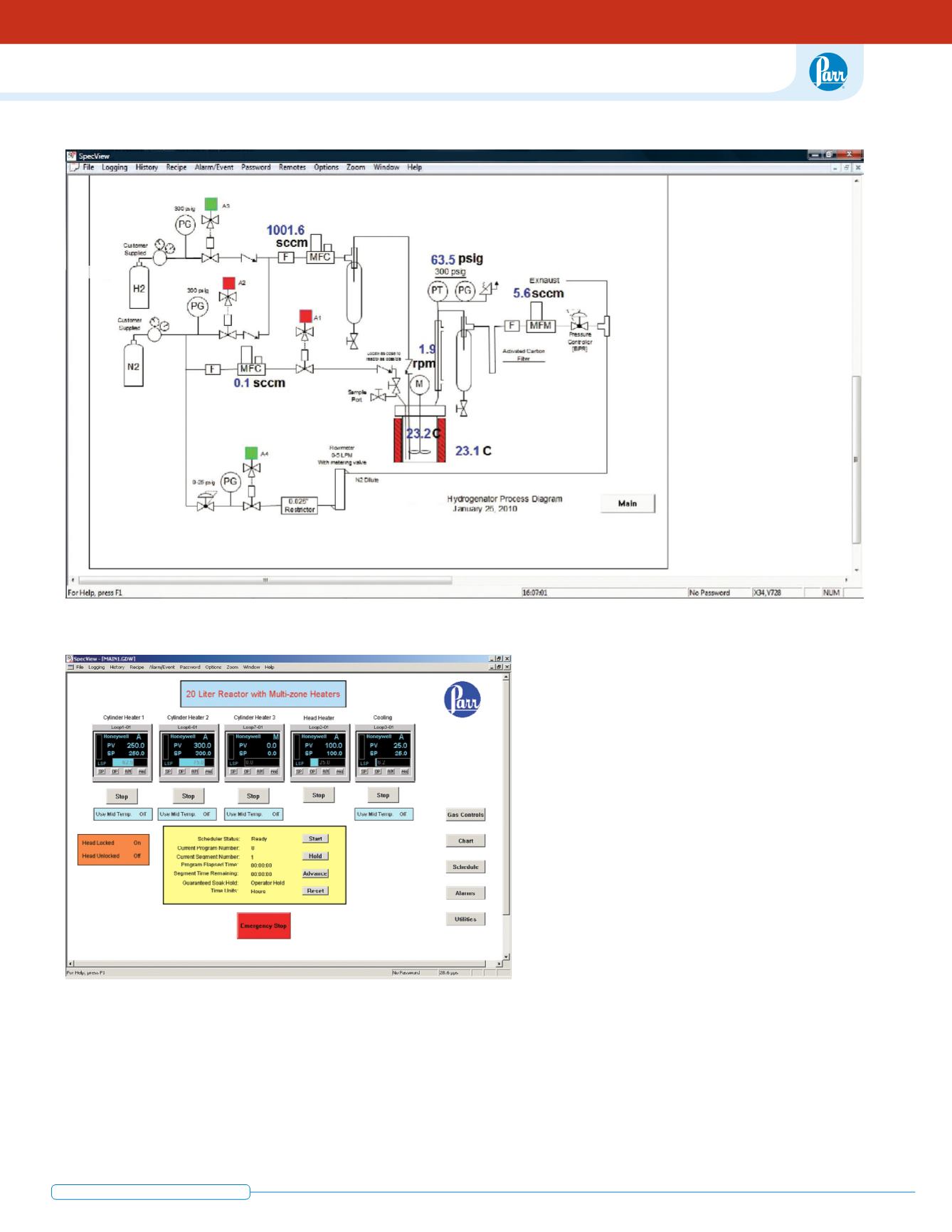

Screenshot of typical 4871 Controller user interface main screen.

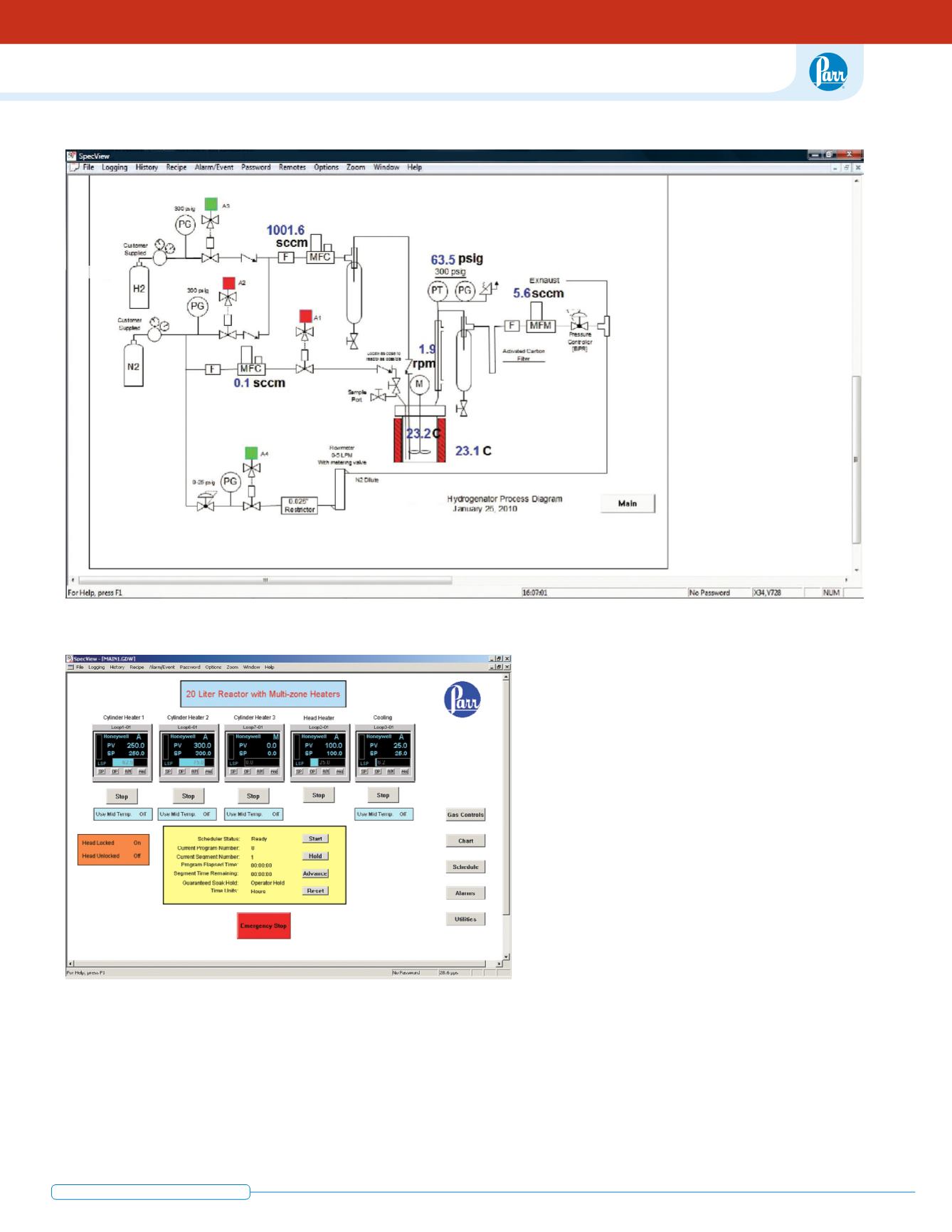

Process Flow Diagram with real-time process renderings and control capabilities.

The 4871 Controller includes Operational

Sequence Control

The sequence control function offered by the

4871 Controller greatly expands the capabilities

of this control for users who wish to control

reactor systems. The operation of valves,

pumps and other peripheral devices can be

programmed on either a time or an event driven

basis. Sequences can be very simple timed

events or they can be very complex with multiple

nested default sequences programmed to occur

only if process feedback indicates a need to take

alternative actions.

Communications Channels

Each 4871 Controller is equipped with a

RS-232 and Ethernet communication port. The

RS-232 port is used to establish fundamental

control logic. The Ethernet port provides com-

munication with the host PC when using the

SpecView GUI program. Multiple controllers,

each with a unique address, can be networked

on the Ethernet interface with a single connec-

tion to the PC.

The principal advantage of the Ethernet

interface is that it allows the user to use an

existing network infrastructure to connect the

controller to the PC. As a result, one can operate

the controller over the network from anywhere

within your facility. Additionally, Internet access