104

P a r r I n s t r u m e n t C o m p a n y

Stirrer Motors and Drives

Torque vs. Stirring Speed

T

he standard, open-type,

variable speed motor

installed on each Parr reactor

will produce stirring speeds

from zero to between 600

and 800 rpm with a torque

adequate to drive the installed

impellers in average viscosity

mixtures. Higher horsepower

motors and special stirrers can

be provided for higher viscosi-

ties. Alternate drive pulleys are

available to produce higher

stirring speeds, but several

basic rules must be considered

when changing any of these

components.

The highest torque from

any motor

is obtained at lower

stirring speeds. Increasing

the stirring speed reduces the

torque in inverse proportion

to the speed. For operations

involving high viscosity

mixtures, the motor size, the

type of impeller and the stir-

ring speed must be matched

to provide an effective mixing

system.

As a general rule,

the mag-

netic coupling installed on each

Parr reactor will have a torque

rating considerably higher than

the torque obtainable from the

motors offered for use with

that apparatus. The goal is to

make the motor the weak link

so that the magnetic stirrer will

be protected. Reference torque

rating for applicable magnetic

drive.

Explosion Proof Motors

Explosion proof motors

designed for Class I, Groups C

and D and Class II, Groups F

and G with variable speed con-

trol can be furnished for most

Parr reactors.

Air Motors

Air-driven motors can be

installed on most reactors. The

horsepower rating, torque, and

available speed are all depen-

dent upon the pressure and

available volume of the driving

air source. Maximum torques

are delivered at relatively

slow speeds and maximum

horsepower is delivered at high

speed.

Geared, Direct Drive Motors

A geared, direct drive motor

can be installed on most fixed

head floor stand reactors. This

is an attractive arrangement for

handling heavy stirring loads.

Any 1/4 hp or larger,

variable-speed standard or

explosion-proof motor can be

used. Gear box drives are avail-

able with ratios of 3:1, 5:1 and

10:1. The 1700 rpm maximum

speed will be reduced in an

amount determined by the

reduction ratio of the gear

box, and the associated torque

values from the table will be

increased in the same ratio.

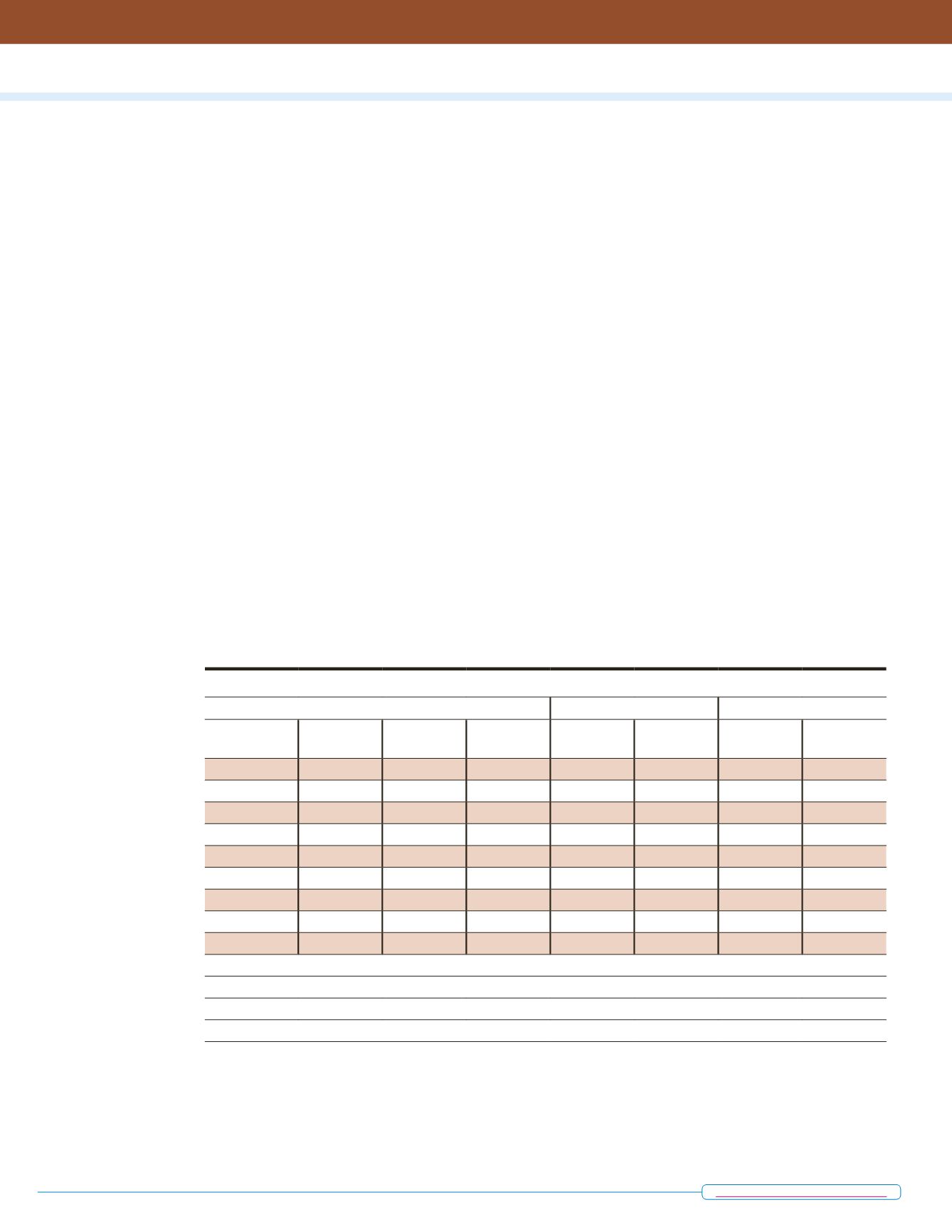

Stirrer Drive Motors

Standard Pulley

Optional Pulley

Motor

Designation

HP

Rating

Explosion

Proof

Variable

Speed

Max Speed,

RPM*

Max Torque,

in-lb

Max Speed,

RPM*

Max Torque,

in-lb

-VS.12

1/8

No

Yes

600

12

1700

4

-XP.25

1/4

Yes

Yes

600

27

1700

9

-AM.25**

1/4

Yes

Yes

1000**

30**

—

—

-VS.25

1/4

No

Yes

600

27

1700

9

-VS.50

1/2

No

Yes

600

54

1700

18

-XP.50

1/2

Yes

Yes

600

54

1700

18

-AM.50**

1/2

Yes

Yes

1000**

66**

—

—

-VS.75

3/4

No

Yes

600

81

1700

27

-XP.75

3/4

Yes

Yes

600

81

1700

27

Values represented are nominal.

VS = variable speed, XP = explosion proof, AM = air motor, 1 in-lb = 0.11 Nm, 1 hp = 0.75 Kw

*Maximum speed values based on “no load”

**HP, RPM, and torque values for air motors are based on a 40psi supply capable of 34cfm for the AM.50 and 10cfm for the AM.25.