74

P a r r I n s t r u m e n t C o m p a n y

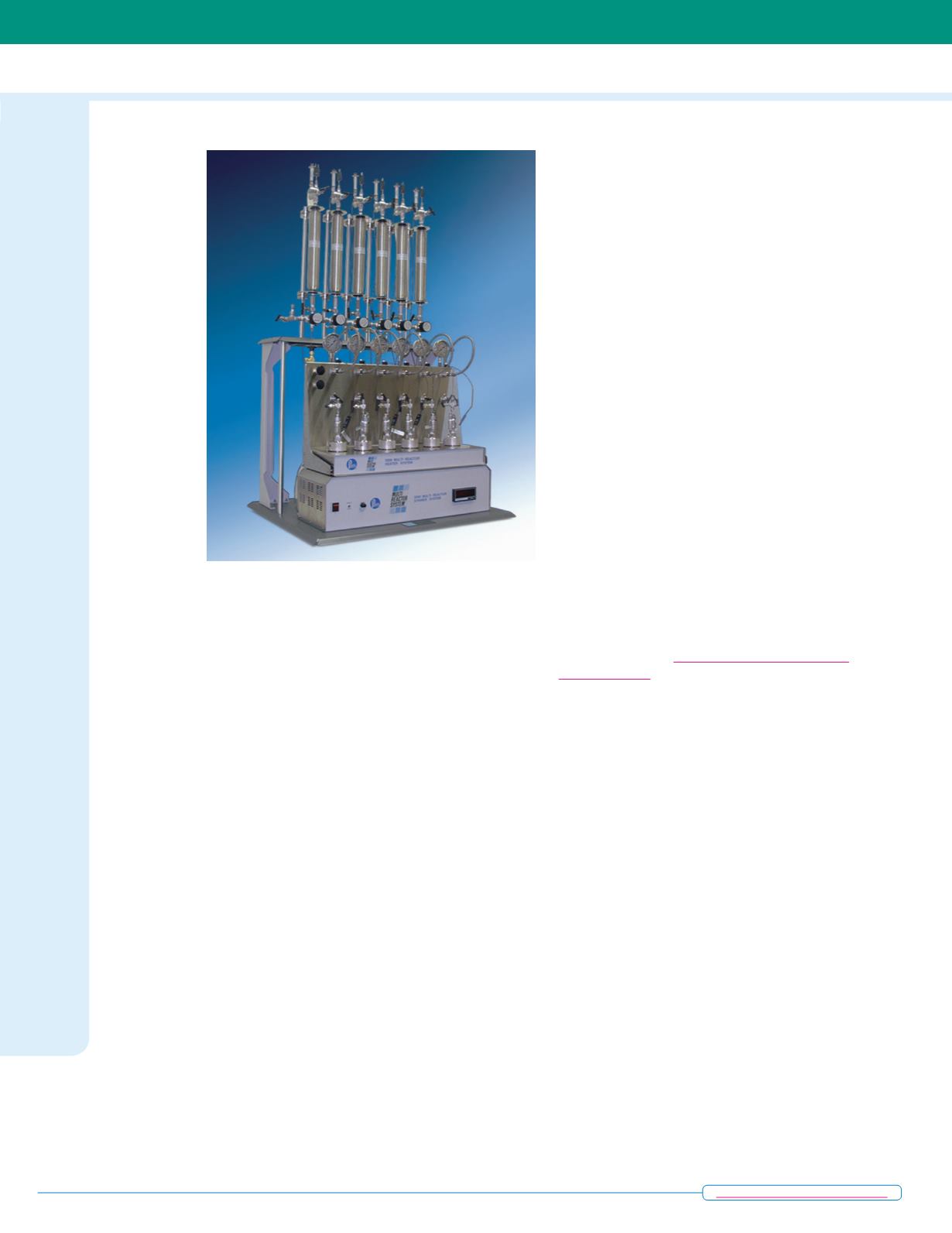

5000 Multiple Reactor System (MRS)

Head Configuration.

Each reaction vessel

is equipped with an inlet valve, exhaust valve,

safety rupture disc, and pressure transducer in

addition to an internal thermocouple. The user

can choose to have the valves, transducer and

rupture disc mounted on a gage block connected

directly to the vessel head, or remotely mounted

on the back panel and connected to the valve

with a quick coupling flexible high pressure

hose. The head mounted design makes it pos-

sible to remove pressurized vessels from the

heater/stirrer assembly or to prefill the vessels

in a remote location. The remote panel mounted

arrangement connects all of the pressure inlets/

outlets to each vessel with a single flexible con-

nection for the greatest ease of handling.

The heads of these vessels can also be modified

to include a dip tube for liquid sampling or a cold

finger for cooling. An optional reactor cooling sup-

port rack is available for air-cooling.

Materials of Construction.

Type 316

Stainless Steel is the standard material of

construction for both the vessel with its wetted

parts and the gage block assemblies exposed

to vapors. For investigators working with sys-

tems containing strong mineral acids or other

more corrosive systems these vessels can be

made of most of the Parr standard materials of

construction.

Stirrer Configuration.

Stirring is accom-

plished by use of either PTFE coated or glass

coated magnetic stirrer bars.

Thermocouple Configuration.

Thermocouples are mounted inside the vessel

for the best temperature monitoring and control.

The thermocouples are protected by stainless

steel sheaths which are inserted into a protective

thermowell. These thermowells make it easy to

install and remove thermocouples from the ves-

sels, and also provide additional chemical and

mechanical protection for the thermocouple.

RTD temperature sensors can be substituted

for users who prefer this method of temperature

measurement.

We also offer a redundant thermocouple

option with the thermocouple positioned in con-

tact with the heater.

Gas Manifold.

The gas inlet manifold can

be designed to handle both a purge gas, usually

nitrogen, and a reactant gas, usually hydrogen.

This can be set up to automatically fill each vessel

to the same initial pressure or to manually fill

each vessel to a unique operating pressure.

4871 Process Controller

The Series 5000 Multiple Reaction System

is controlled by a dedicated Parr 4871 Process

Controller. A detailed description of this con-

troller is found in Chapter 4 of this catalog,

pages 95-100.

For this application the controller is set up

to provide:

• Temperature monitoring and PID control

of each individual reactor.

• Pressure monitoring of each individual

reactor.

• Data logging of temperature and pressure

in each reactor.

• Control and logging of the common stirring

speed of the reactors.

The controller provides Ramp & Soak pro-

gramming for individual reaction vessels, digital

inputs and outputs for interlocks, alarms or

other safety features, and additional analog and

digital inputs and outputs to control flow meters

or other accessories which might be added at

some future date. The user’s control station is a

PC running any current Windows operating sys-

tem. A simplified graphical user interface has

been designed for the control and monitoring of

the Series 5000 Multiple Reaction System. The

PC is used strictly as the user interface and data

logging module. All control actions are gener

ated in the 4871 Process Controller (not the PC).

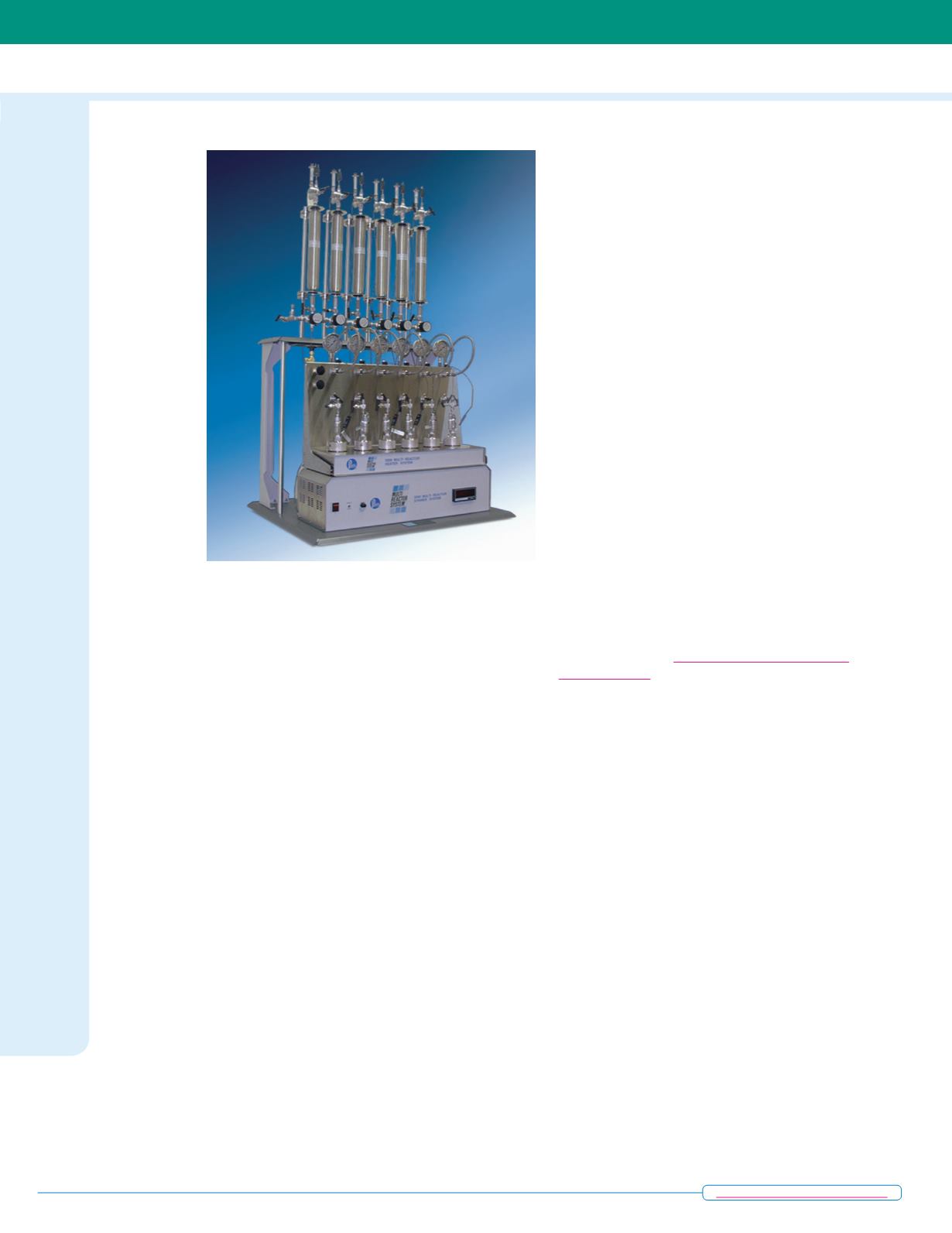

MRS with individually controlled Gas Burettes.