81

P a r r I n s t r u m e n t C o m p a n y

1 - 8 0 0 - 8 7 2 - 7 7 2 0

3

S p e c i a l t y & C u s t o m R e a c t o r s

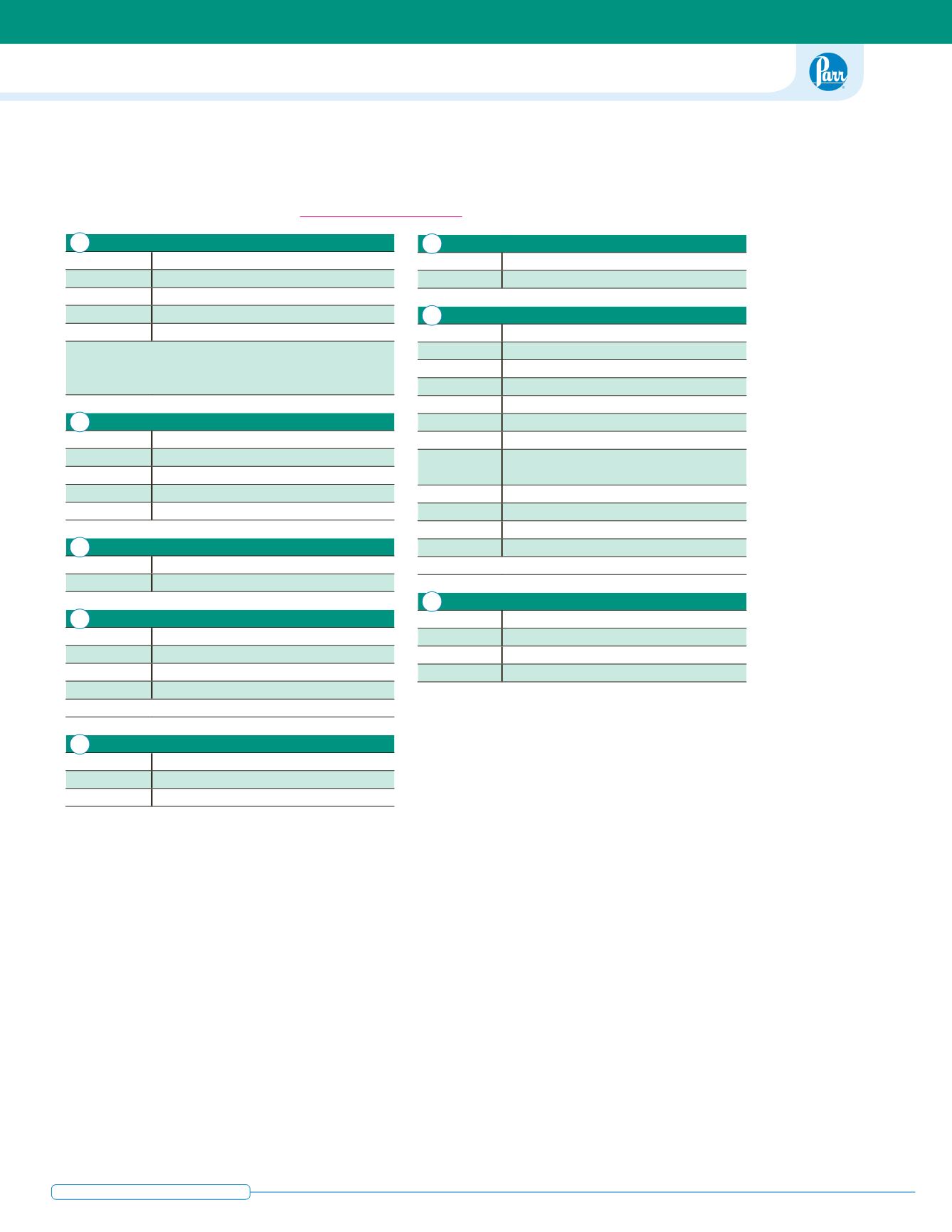

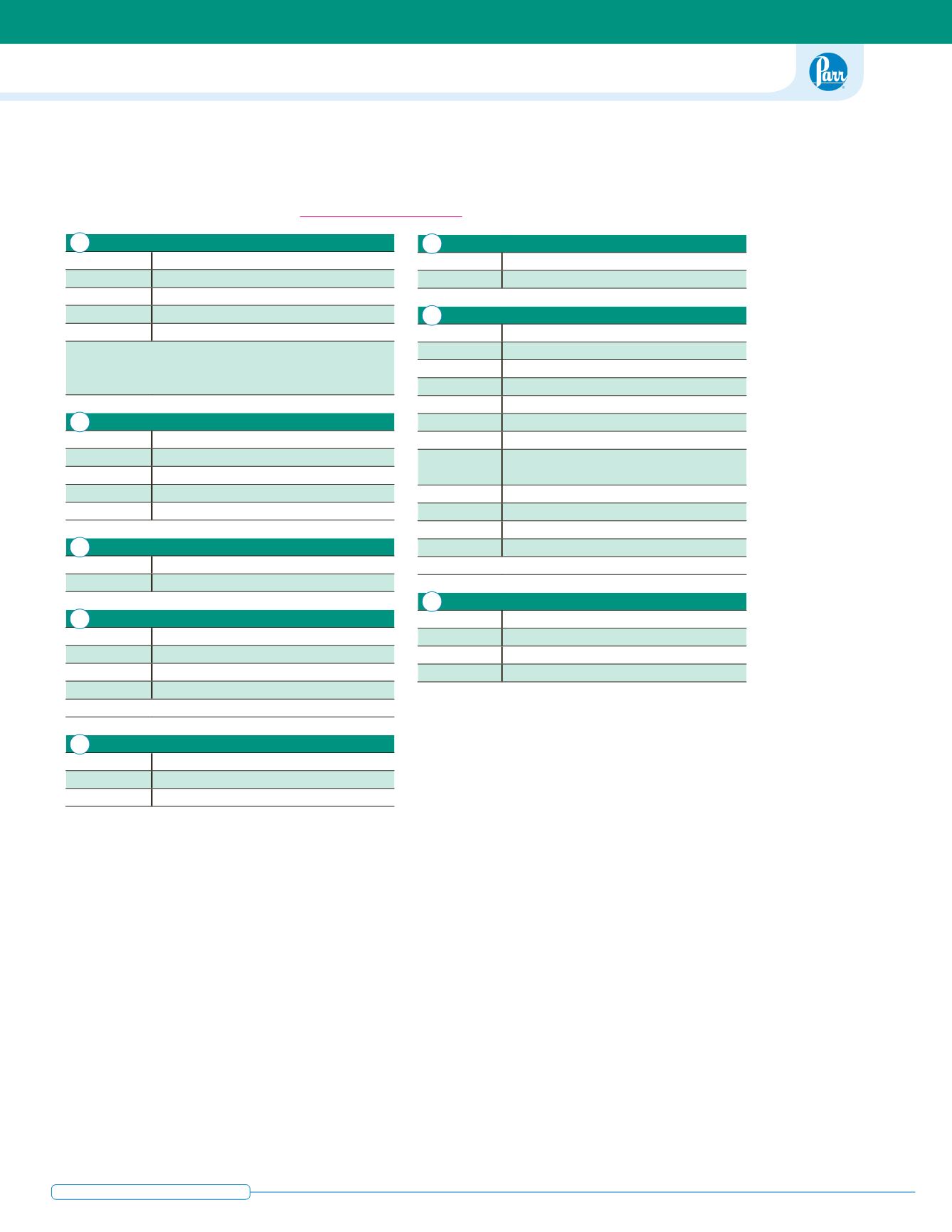

Series 5400 Ordering Guide

Base Model

Model No.

Size

5401

3/8 in.

5402

1/2 in.

5403

1.0 in.

5404

1.5 in.

Add suffix F for Floor Stand mounting

Add suffix B for Bench Top mounting

Add suffix C for Cart mounting

Materials of Construction

-SS

T316 Stainless Steel

-HC

Alloy C-276

-TI

Titanium

-IN

Alloy 600

-MO

Alloy 400

Electrical Supply

-115

115 VAC

-230

230 VAC

Heater Options

-ST1(#)

Split Tube, 1-Zone

-ST3(#)

Split Tube, 3-Zone

-FM(#)

Flexible Mantle

-WJ(#)

Welded Jacket

Add suffix (6), (12), (24), (36) for heated length in inches.

Maximum Operating Pressure

-1500

1500 psi / 100 bar

-3000

3000 psi / 200 bar

-4500

4500 psi / 300 bar

Controller

-PCC

PC-based Process Control (4871-style)

-DCS

Distributed Control System

Custom Options

-GF(#)

Number of Gas Feeds

-PL

Purge Gas Feed Line

-LF(#)

Number of Liquid Feeds

-ISP

Internal Pre-heat Spiral (5403/5404 only)

-CSS

Catalyst Support Spools (5403/5404 only)

-ITW

Internal Thermowell, with T/C

-CHX

Cooling Heat Exchanger

-GLS(#)

Gas/Liquid Separator, Volume (300), (600),

(1000), (2000) in mL.

-SPH

Separator Heater

-TR(#)

Number of Gas Tank Regulators

-AP*

Automated Pressure Control

-ASV*

Automated Shut-off Valves

*Available only with 4871 Process Control

Certifications

-No Symbol

No Certification

-ASME

ASME Certification

-CE/PED

European Community Certification/Pressure

-P

Parr Certification

A

F

G

H

B

C

D

E

The Order No. for the Base System is:

5402C-SS-115-ST3(24)-3000-DCS-GF2-LF1-ITW-GLS1000

A composite identification number to be used when ordering a 5400 Series Reactor can be

developed by combining individual symbols from the separate sections below. For more information

on how to use this ordering guide, please return to page 27.