86

P a r r I n s t r u m e n t C o m p a n y

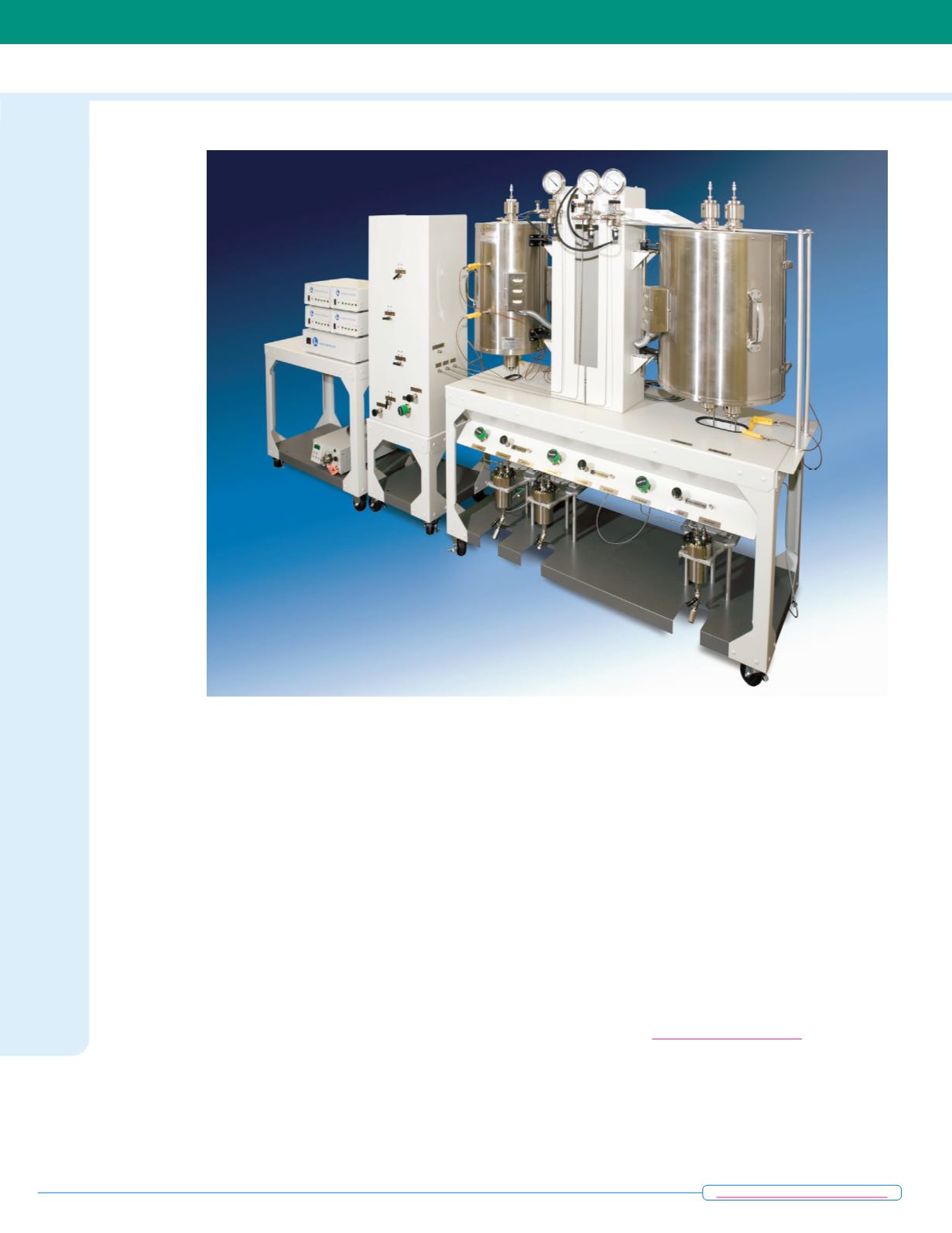

GTO (Gas-To-Oil) System

T

his system incorporates three tubular reactors

that can be configured as required to oper-

ate in a strictly parallel fashion or in a cascade

arrangement where the products from one

reactor are immediately directed to a second

reactor. This type of system can support reaction

schemes including but not limited to the Fisher-

Tropsch process, methanation reactions, steam

reforming and other similar processes.

The Fisher-Tropsch process converts carbon

monoxide and hydrogen into oils or fuels that

can substitute for petroleum products. The reac-

tion uses a catalyst based on iron or cobalt and

is fueled by the partial oxidation of coal or wood-

based materials such as ethanol, methanol, or

syngas. This reaction scheme offers a promising

route to producing economical renewable trans-

portation fuels. By carefully controlling the

temperature and oxygen content, resulting prod-

ucts can range from syngas to “green diesel”.

One of the unique features of this system is

a gas blending subsystem capable of mixing up

to four reactant gases followed by a controlled

delivery of this blended mixture to each of

the three reactors via dedicated mass flow

controllers.

Downstream components for each reactor

include a heat exchanger/condenser, a gas/

liquid separator (product receiver) and a fully

automated back pressure regulator. The system

includes support for introducing liquid reactants

via a high pressure metering pump. The system

comes completely automated with the addition

of the highly versatile 4871 Process Controller

(not pictured, see chapter 4, page 95).

Parr GTO System