114

P a r r I n s t r u m e n t C o m p a n y

One of the modifications

most frequently requested is

a port or other means to feed

liquids, solids, or slurries into

the vessel without removing

the head. This can be done in

various ways.

Ball Valve Solids Charging

Ports

A

ball valve with a 3/8"

diameter opening can

be installed on any one liter

or larger vessel and used

in conjunction with a high

pressure pipette for injecting

slurries under pressure. These

are opened or closed with a

quarter turn of the handle.

Larger diameter valves are

available for 1 gallon and

larger vessels. These ball

valves will withstand the full

pressure developed in a reac-

tor at moderate temperatures,

but their pressure rating falls

off rapidly at temperatures

above 100 °C.

Solids Charging Ports

Part No.

Nominal

Size

Orifice

Diameter,

in.

A143VB

1/4" NPT (F)

0.250

A132VB

3/8" NPT (F)

0.375

396VBAD 1/2" NPT (F) 0.406

Capped Openings

Reactor

Available

Fitting Sizes

Mini

1/4" NPT (F)

1 & 2 Liter

3/8" NPT (F)

Gallon & up 1/2" NPT (F)

Liquid

Complete

Reactor

Mounting

Size, cc

Assembly No.

Thread

Mini

6

A550HC3

1/8" NPT

One Liter

8

A550HC

1/8" NPT

Larger

20

A550HC2

1/8" NPT

A550HC Open

Capped Openings

A

capped opening in the

head of a reactor can

serve as a convenient solids

charging port, offering the

largest possible diameter

and a significantly shorter

passage than a ball valve. A

male connector with a cap

is usually used to close the

opening. These will have a

reliable metal to metal seal

and the ability to withstand the

full temperature and pressure

for which the vessel is rated.

Tubing can be connected

to the fitting, but this type

of connector is normally

used only where solids or

slurries will be added at

atmospheric pressure.

Catalyst Addition Devices

P

arr has developed a unique

device for adding small

amounts of solids (or liquids)

from a sealed container held

within a reactor. It is of particu-

lar interest to users performing

kinetic studies of catalytic

reactions. This device consists

of a small cylindrical chamber

with a cap that is sealed to

the body with an O-ring. It

attaches to the underside of

the vessel head with a 1/8"

NPT connection. To discharge

the contents of the holder, gas

pressure is applied through a

valve installed on the top of

the head. When the applied

pressure is greater than the

pressure within the reac-

tor, the cap is forced open

and the catalyst or other

contents of the holder will

be released into the reac-

tor. This device works best

in the taller, 450 mL and

600 mL Mini Reactors,

and in the 1 liter and

larger Parr Reactors.

A550HC Catalyst

Addition Device

Solids Charging

Auger

A143VB Ball Valve

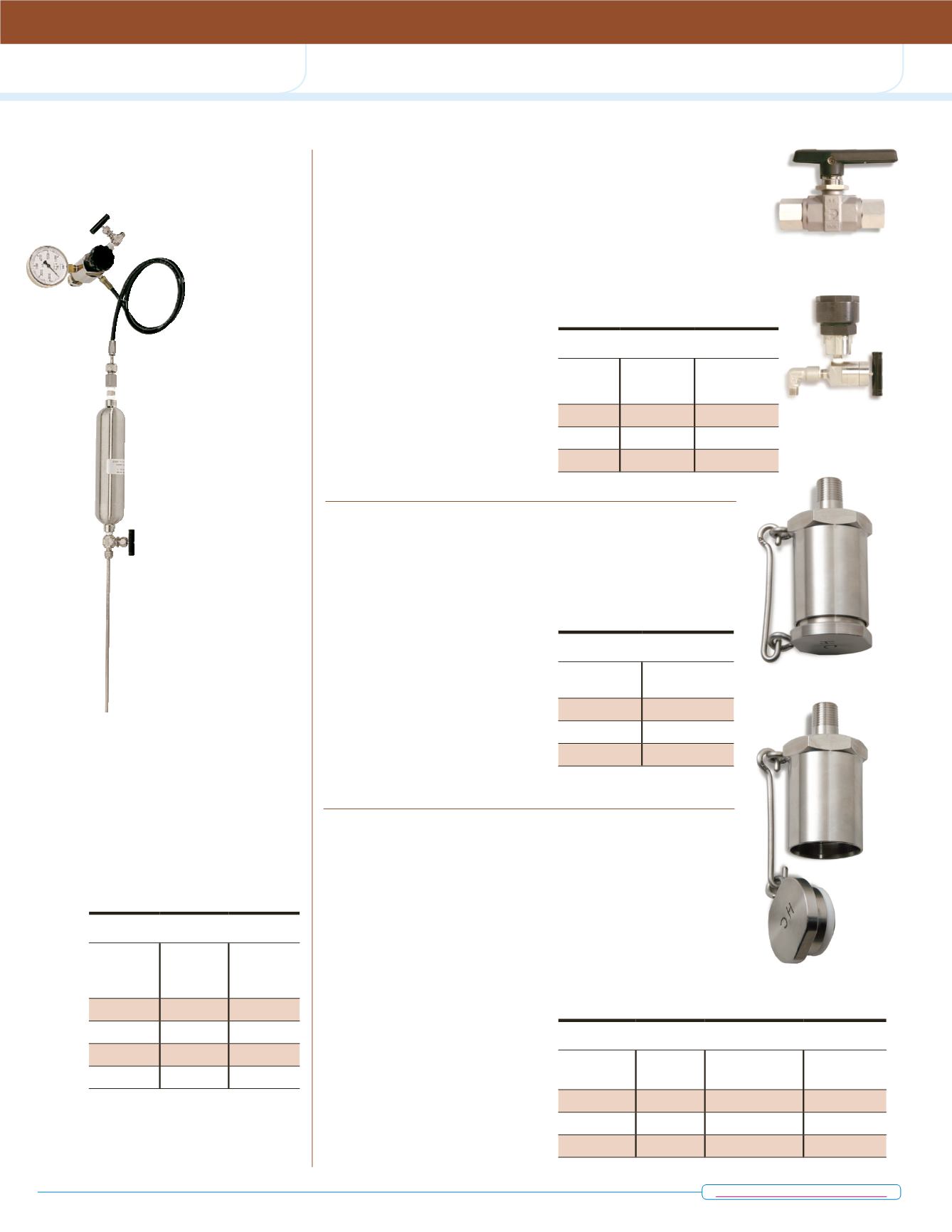

Liquid Charging Pipettes

T

o introduce liquids into

reactors or vessels at

elevated pressures,

the most economical

way is to use

a pressure

pipette as a

secondary

vessel. These

are often used

for liquid addition

to a batch process.

Liquid is forced into the

reactor from the pipette

by applying gas pres-

sure to the pipette

greater than the pres-

sure within the vessel.

If the passages in the

connecting line are

large enough, slurries

or catalyst suspen-

sions can also be

charged into the reac-

tor in this manner.

The pipettes listed

below offer a choice of

volumes and are rated

for pressures to 1800 psi.

They include a nitrogen

filling connection for

attachment to a nitrogen

tank. More elaborate

pipette systems can be

assembled to special order to

include additional fittings, such

as a pressure gage for the

pipette, a pressure relief valve

or a large opening ball valve.

Special pipettes can also be

furnished for higher pressures

to 5000 psi.

A2113HC

Liquid

Charging

Pipette

Liquid Charging Pipettes

Part No.

Pipette

Volume,

mL

Pressure

Rating,

psi

A2113HC3 50

1800

A2113HC4 150

1800

A2113HC 300

1800

A2113HC2 1000

1800

Solids Charging Systems