110

P a r r I n s t r u m e n t C o m p a n y

Safety Rupture Discs

We have selected alloy 600 as the standard

material for these rupture discs. It provides

excellent corrosion resistance while retaining

over 90% of its room temperature rating at

temperatures up to 450 °C. For added corrosion

resistance we can furnish these discs with gold

facing or replace them with discs made of Alloy

C276. Discs can be produced to match any oper-

ating pressure and temperature above the stated

minimums.

Parr reactors and pressure vessels from

25 mL to 2000 mL use the 526HC alloy 600 disc

or 581HC alloy 600 with gold facing. The 1 gallon

and larger use the 708HC series discs. The 4580

reactor systems use the 1415HC series discs.

For a complete listing of part numbers, burst

ranges and materials see Manual 231M.

In general,

the 1000 psi disc in the

526HC/581HC series discs and the 800 psi in

the 708HC are the lowest available ranges in

the alloy 600 material. Alternate disc materials

are available but they do not offer the same

corrosion resistant properties and temperature

capabilities.

For applications where users prefer a lower

range pressure gage, we would add a spring

loaded relief valve set to protect the gage and a

1000 psi rupture disc as the fail safe protection.

Users are invited to contact the Parr Technical

Support Staff with requirements for special

rupture discs.

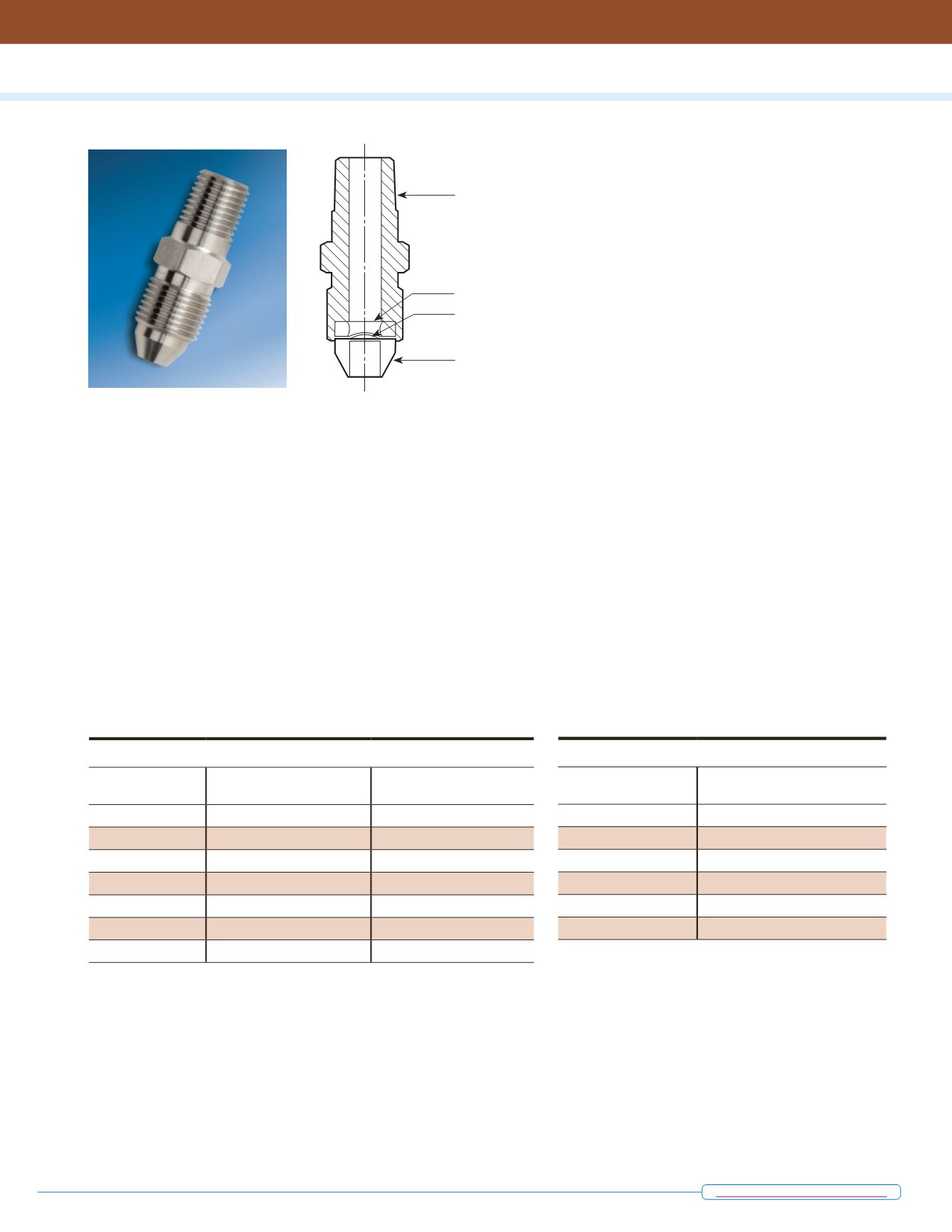

1/4" NPT (M)

Rupture Disc

Orifice Ring

Nose Cone

Rupture Discs for 1/4" Orifice

Burst Rating, psig Inconel Disc

Gold-Faced Inconel Disc

1000

526HCPD

581HCPD

2000

526HCPF

581HCPF

3000

526HCPG

581HCPG

4000

526HCP40CT

581HCP40CT

5000

526HCPH

581HCPH

8000

526HCPJ

581HCPJ

10000

526HCP100CT

Rupture Discs for 1/2" Orifice

Burst Rating, psig

Inconel Disc

1000

708HCP10CT

1500

708HCP16CT

2000

708HCP20CT

3000

708HCP30CT

3000

1415HCP30CT

4500

1415HCP45CT

P

arr Pressure Vessels are protected by

custom built rupture discs furnished by

Fike

®

Corporation, a specialist in this exotic art.

Examination of these discs will indicate that

each of these discs is domed. This dome was

produced at the factory by taking the individual

disc to 70% of its burst pressure.

The ASME as well as other pressure vessel

codes dictate that pressure vessels must be

equipped with a rupture disc designed to burst

no higher than the design pressure of the ves-

sel. For pressure loads that do not cycle rapidly

such as our vessels, Fike suggests limiting the

actual operating pressure to no more than 90%

of its burst pressure. This combination will limit

operating pressures to no more than 90% of the

design pressure of the vessel.

A888HC2 Rupture

Disc Assembly