116

P a r r I n s t r u m e n t C o m p a n y

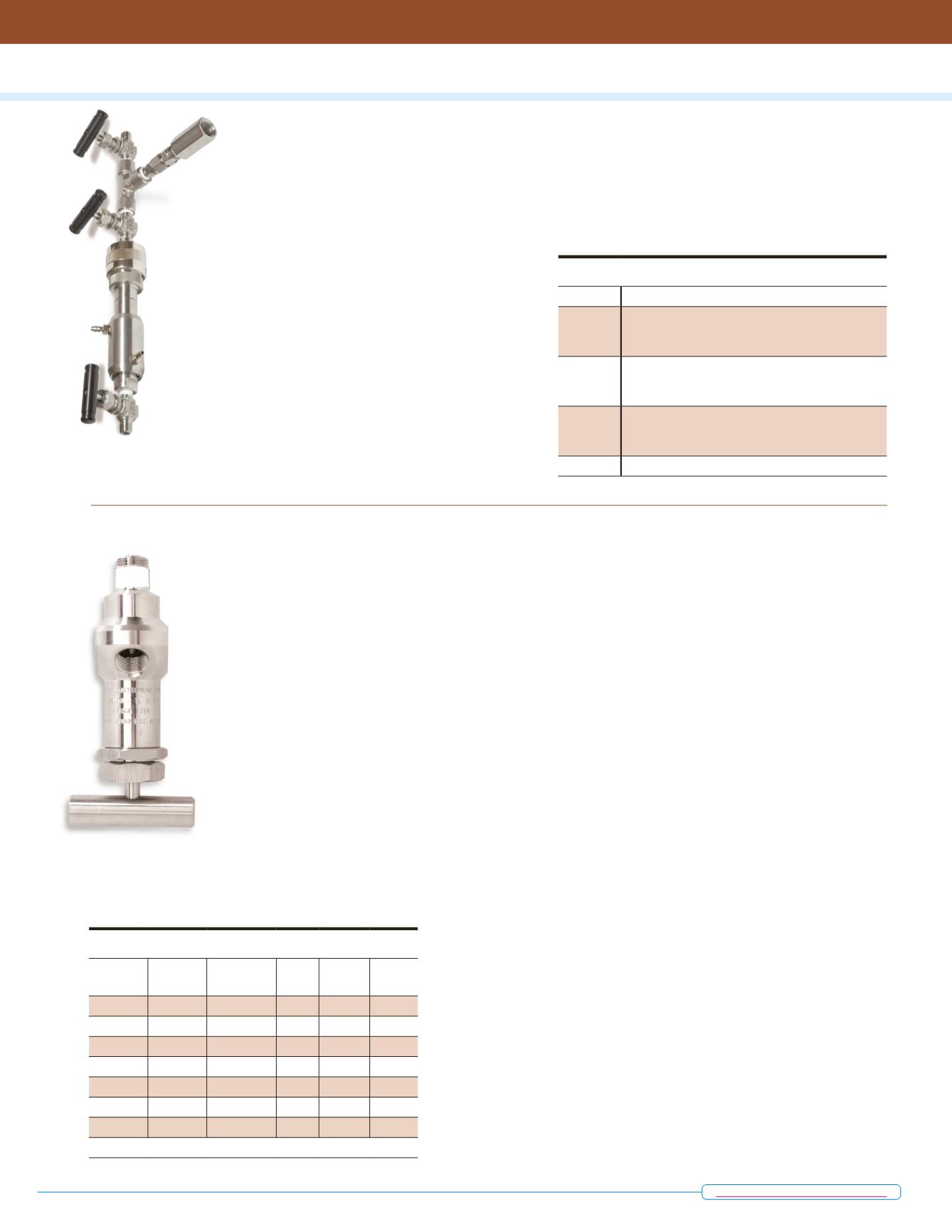

Sample Collection Vessels

B

ottom drain valves can be added to most

Parr reactors. These valves are particularly

useful for those working with polymers or other

material that must be discharged from the

reactor while they are still hot and before they

can solidify. These valves are also quite useful

for the 1 gallon and larger vessels which are

too large to conveniently lift from the heater

for product recovery. Bottom valves are rarely

installed on the micro and mini reactors with

their small volumes and light vessel weights.

The standard bottom drain valve

has a

rising stem, that is flush with the inside cylinder

bottom so that there is no dead space between

the bottom of the vessel and the shut off point

of the valve. In the fully open position the stem

is retracted completely to open a clear passage

for draining the vessel.

When the valve is reclosed, any material in

this passage will be pushed back into the reac-

tor by the

rising stem.

Valves with

3/8" diameter

clear passage

are recom-

mended for

vessels with

volumes

from 1000

mL to 2

gallons. A

1/4" valve is

available for

600 mL and

smaller vessels. High pressure and larger diam-

eter valves are available where required.

These valves will withstand

the full operat-

ing pressures and temperatures of the vessels

in which they are installed. They are available

in nearly all of the current Parr materials of

construction. Air actuated valves are available

for larger reactors. Users can also specify that a

reactor ordered with a bottom valve shall have a

tapered bottom so that it will drain easily through

the valve opening.

Not all Parr reactors will accept a bottom

drain valve. Since the valve extends approxi-

mately 8 inches below the bottom of the vessel,

the entire vessel must be raised by this amount

to accommodate the valve. This makes some

models too tall for convenient bench top opera-

tion. The specification tables for each model will

identify those reactors in which a bottom drain

can be readily installed, and those which will

not accept a bottom drain, or those which will

require custom modification of the heater and

support stand to accommodate a bottom valve.

Needle Valves and Ball Valves

N

eedle valves and ball valves can also be

installed as bottom outlet valves. Needle

valves are generally used on the smaller reactors.

While ball valves can be used for large discharge

passages, they are generally limited in their

operating temperature/pressure capabilities and

they leave a fairly large dead space between the

bottom of the vessel and the seat of the valve.

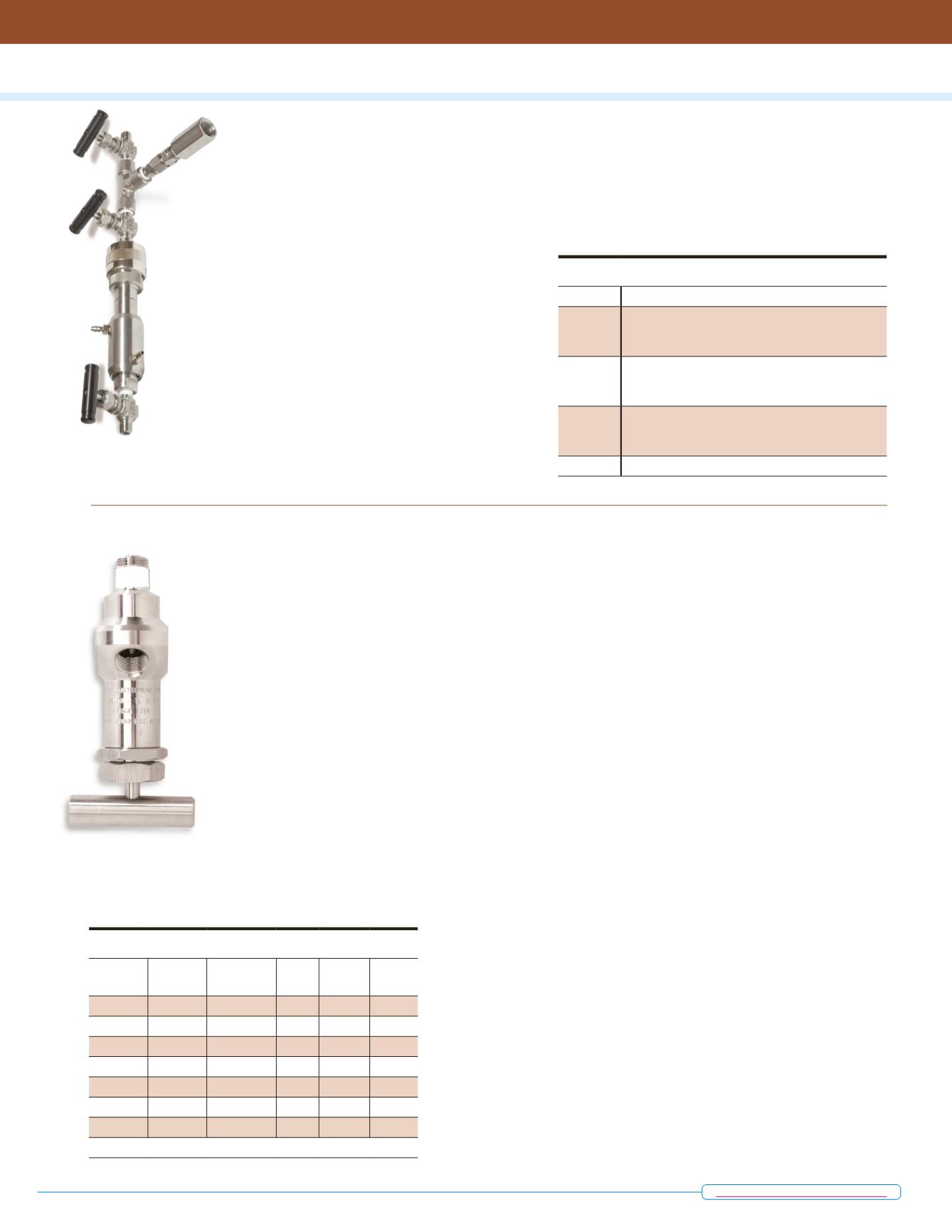

Bottom Drain Valves

Part No.

Opening

Dia., in.

Outlet

Connection

Max.

Press.,

psi

Max.

Temp,

°C

Seal

A485VB 0.25

1/4" NPT (F) 3000 225

PTFE

A485VB2 0.25

1/4" NPT (F) 3000 350

Silver

A465VB 0.38

3/8" NPT (F) 2000 350

Grafoil

A465VB2* 0.38

3/8" NPT (F) 2000 350

Grafoil

A465VB3 0.38

3/8" NPT (F) 2000 350

Silver

A177VB 0.31

3/8" NPT (F) 5000 500

Grafoil

A296VB 0.69

1" NPT (F)

1900 265

PTFE

* Set up for a Band Heater.

Sample Collection Vessels

Part No.

Description

4351

Sample Collection vessel, 10 mL, with cooling

sleeve, isolation & vent valves for connection to

1/8”NPT valves

4352

Sample Collection vessel, 10 mL, with cooling

sleeve, isolation & vent valves for connection to

1/4”NPT valves

4353

Sample Collection vessel, 10 mL, with cooling

sleeve, isolation & vent valves for connection to

3/8”NPT valves

-D

Optional Drain Valve

A465VB Bottom

Drain Valve

A

sample collection vessel can be added to

most reactor systems. Designed to efficiently

and safely allow for the withdrawal of liquid or

vapor samples at elevated temperatures and

pressures, this quick close, O-ring seal vessel has

a volume of 10 mL and is designed for operating

pressures to 3000 psi (200 bar).

The typical arrangement for this sample ves-

sel includes a cooling sleeve, isolation and vent

valves. A drain valve may also be added to

the vessel.

The isolation valve is mounted at the head of

this vessel and is used to seal the vessel once the

sample is transferred. The vent valve is installed

in a tee and is used to release any residual pres-

sure in the line between the sample valve and the

sample vessel. Samples can be removed either

by opening the collection vessel and pouring it

out or by use of the drain valve.

Standard material of construction is T316

Stainless Steel but it can be provided in any of

the other alloys if required. A high pressure sam-

ple collection vessel without a cooling sleeve for

pressures to 5000 psi is available upon request.

Bottom Drain Valves