Series 4590 Micro Reactors

3

B u l l e t i n 5 4 0 0

1 - 8 0 0 - 8 7 2 - 7 7 2 0

When ordering mass flow controllers, you will

need to specify:

1. Type of gas to be metered (e.g. N2, H2, CH4)

2. Maximum operating pressure of the gas (100

or 300 bar)

3. Maximum flow rate range in standard cc’s per

minute (sccm)

4. Pressure for calibration of the instrument

Mass flow controllers are available for use to

1500 psi and to 4500 psi. Considerable savings

can be obtained if the mass flow controller is to

be used only to 1500 psi.

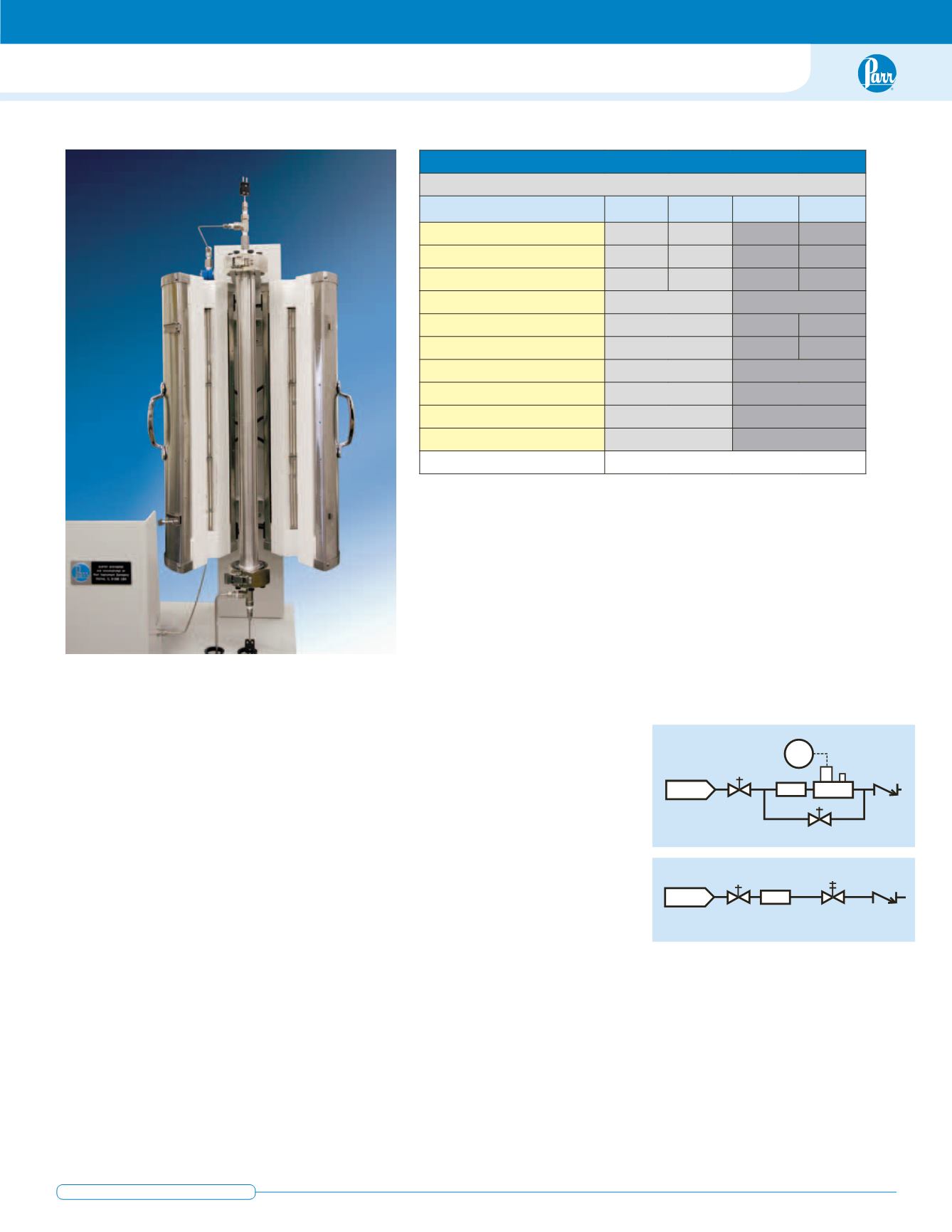

The schematic at right depicts

the installation of a mass flow

controller for the introduction of

gas to a continuous-flow reaction

system. Such installations are

enhanced with the addition of a

by-pass valve for rapid filling.

A purge line can also be

added. It is typically used for

feeding nitrogen or helium to

remove air before reaction or to

remove reactive gases before

opening the reactor at the end of

a run. The purge line includes a shut-off valve,

metering valve, and a reverse-flow check valve.

Shut-off valves can be automated when using

a 4871 Control system.

Liquid Metering Pumps

High pressure piston pumps are most often

used to inject liquids into a pressurized reactor

operating in a continuous-flow mode. For low

flow rates, HPLC pumps, many of which are

rated for 5000 psig, are excellent choices.

Series 5400 Tubular Reactor System Specifications

Shaded bar indicates specifications that change within series.

Model Number

5401 5402 5403 5404

Sizes

3/8 in.

1/2 in.

1.0 in.

1.5 in.

O.D. / I.D. (in.)

0.38/0.28 0.50/0.37

1.9/1.0

2.0/1.5

O.D. / I.D. (mm)

9.5/7.0

13/9.4

48/25

51/38

Heated Length (in.)

6, 12, 24

12, 24, 36

Max. Pressure (psi)

3000

5000

3000

Max. Temperature

550

550

350

Support Spools

No

Yes

Spiral Pre-Heat

No

Yes

No. Ports in Top Head

1

4

No. Ports in Bottom Head

1

4

Internal Thermocouple

Yes

temperature as the core of the reactor. The heater

length is normally divided into one, two, or three

separate heating zones, although it can be split

into as many zones as required.

We can furnish either a fixed internal ther-

mocouple in each zone or a single movable

thermocouple that can be used to measure the

temperature at points along the catalyst bed.

External thermocouples are typically provided for

control of each zone of the heater.

Gas Feed Systems

Various gas feeds can be set up and operated

from a

Gas Distribution Panel

. In order to

deliver a constant flow of gas to a reactor, it is

necessary to provide gas at a constant pressure

to an electronic

Mass Flow Controller

. This

instrument will compare the actual flow rate

delivered to the set point chosen by the user, and

automatically adjust an integral control valve to

assure a constant flow. Care must be taken to

size these controllers for the specific gas, the flow

rate, and the pressure of operation. A mass flow

controller needs a power supply and read-out

device, as well as a means of introducing the

desired set point.

FIC

Gas

F MFC

Gas

F

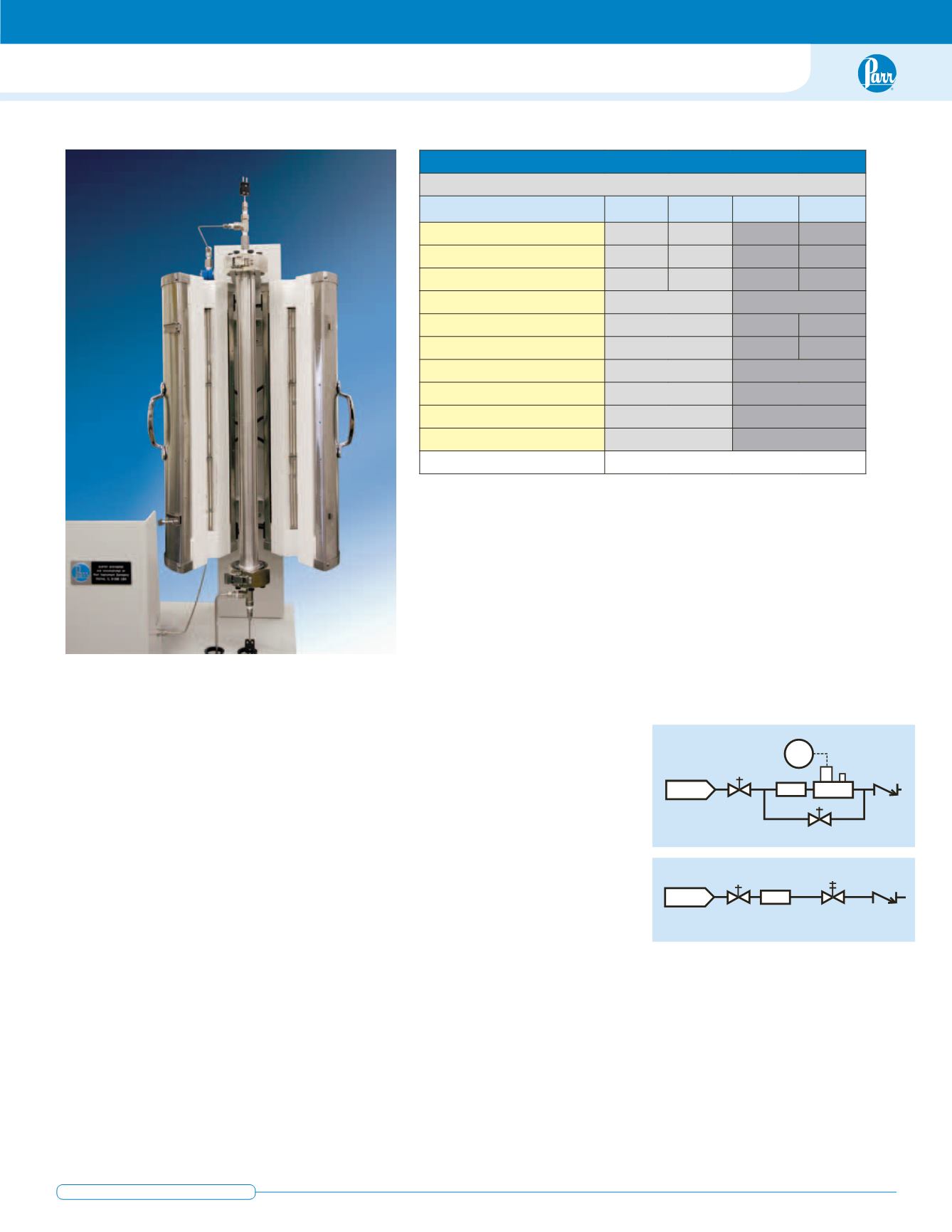

3-Zone Split Tube Furnace with 1" I.D. Tubular Reactor.

T u b u l a r R e a c t o r S y s t e m s