6

P a r r I n s t r u m e n t C o m p a n y

w w w . p a r r i n s t . c o m

Series 5400 Continuous Flow Tubular Reactors

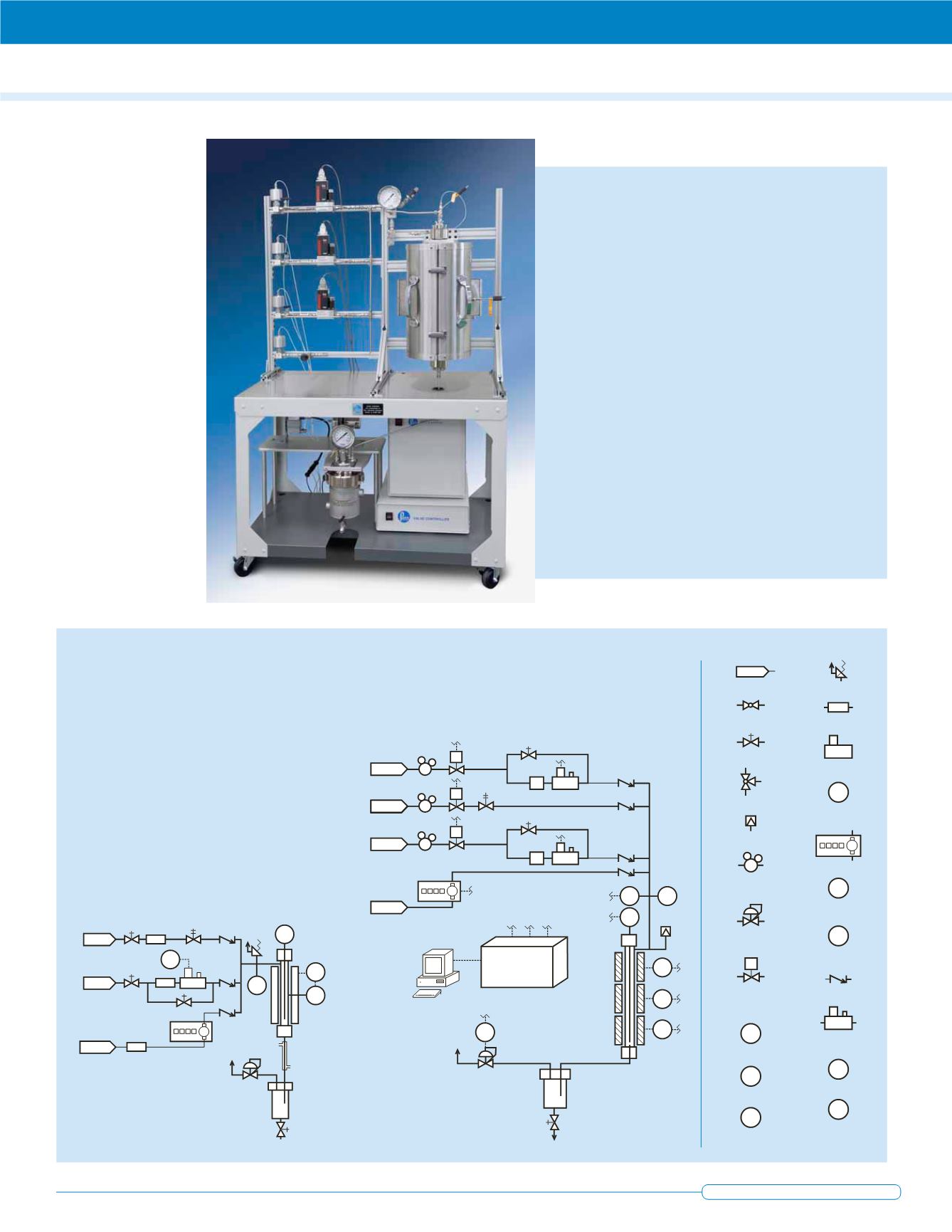

Below and right are schematic

representations of typical tubular

reactor systems, along with a symbols

chart to facilitate understanding. We

have provided the ordering number

for each of these examples.

Order No.: 5402C-SS-115-FM-

1500-DCS-GF(1)-PL-LF(1)-ITW-CHX-

GLS(300)

Order No.: 5403F-SS-230-ST3(24)-3000-

PCC-GF(2)-PL-LF(1)-ISP-CSS-ITW-GLS(600)-

TR(3)-AP-ASV

Tubular Reactor System with Three-Zone Heater,

600 mL Separator Vessel and 4871 Controller

Single-zone Tubular Reactor System with

one Liquid Feed, one Gas Feed, and a Purge

Line.

GAS 1

S

Purge

PT

T/C

T/C

T/C

BPR

Vent

T/C

Gas1

S

MFC

F

Gas 2

S

MFC

F

Liquid

4871

Process

Controller

PIC

PG

Gas

FIC

Gas

Liquid

F

F

F

MFC

T/C

PT

T/C

TIC

Key to Symbols

Inlet

PG

Pressure Gage

PI

Pressure Indicator

PT

Pressure

Transducer

T/C

Thermocouple

FIC

Flow Indicating

Controller

PIC

Pressure Indicating

Controller

Ball Valve

Metering

Rupture Disc

3-way

Check Valve

Relief Valve

F

Filter

MFC

Mass Flow

Controller

SIC

Speed Indicating

Controller

MFM

Mass Flow Meter

TIC

Temperature

Indicating

Controller

Pump

Tank Pressure

Regulator

Back Pressure

Regulator

S

Electric-Actuated

Air-Operated

Solenoid Valve

< Synthesis gas (H2/CO) related chemistry is studied with this

30 cm long tubular reactor. This system features the following

main system components:

Three gas mass flow controllers for hydrogen, carbon

monoxide and carbon dioxide. Each MFC is equipped with an

automated air piloted valve to ensure a positive shutoff of the

reactant gas flow.

The 2.5 cm ID reactor and its associated single zone heater.

The reactor is rated for use up to 100 bar @ 550 ˚C and is

equipped with an internal pre-heater and catalyst spools for

easily changing the catalyst loading.

A jacketed gas/liquid product separator coupled with an

automated back pressure regulating system. The jacket is

used for cooling the reaction products.

The process controller and valve interface are conveniently

located on the lower shelf of the moveable reactor stand.

The system was provided with a high pressure liquid meter-

ing pump (not shown) to optionally introduce liquid reactants

into the reactor.

This system is used primarily to facilitate the study and

development of industrial scale catalysts from biomass ash

and char, focusing on engineered manipulation of the char

structure and surface to enhance catalytic activity and selec-

tivity. The emphasis is on catalysts for the synthesis of liquid

fuels and chemicals such as the conversion of synthesis gas

to mixed alcohols.

Reactor Schematic Examples and

their Respective Order Numbers