1 - 8 0 0 - 8 7 2 - 7 7 2 0

F l u i d i z e d B e d R e a c t o r s

3

P a r r I n s t r u m e n t C o m p a n y

• A gas handling and mix-

ing sub-system used to

blend and regulate the

flow of reactant gas to

the bottom of the reactor.

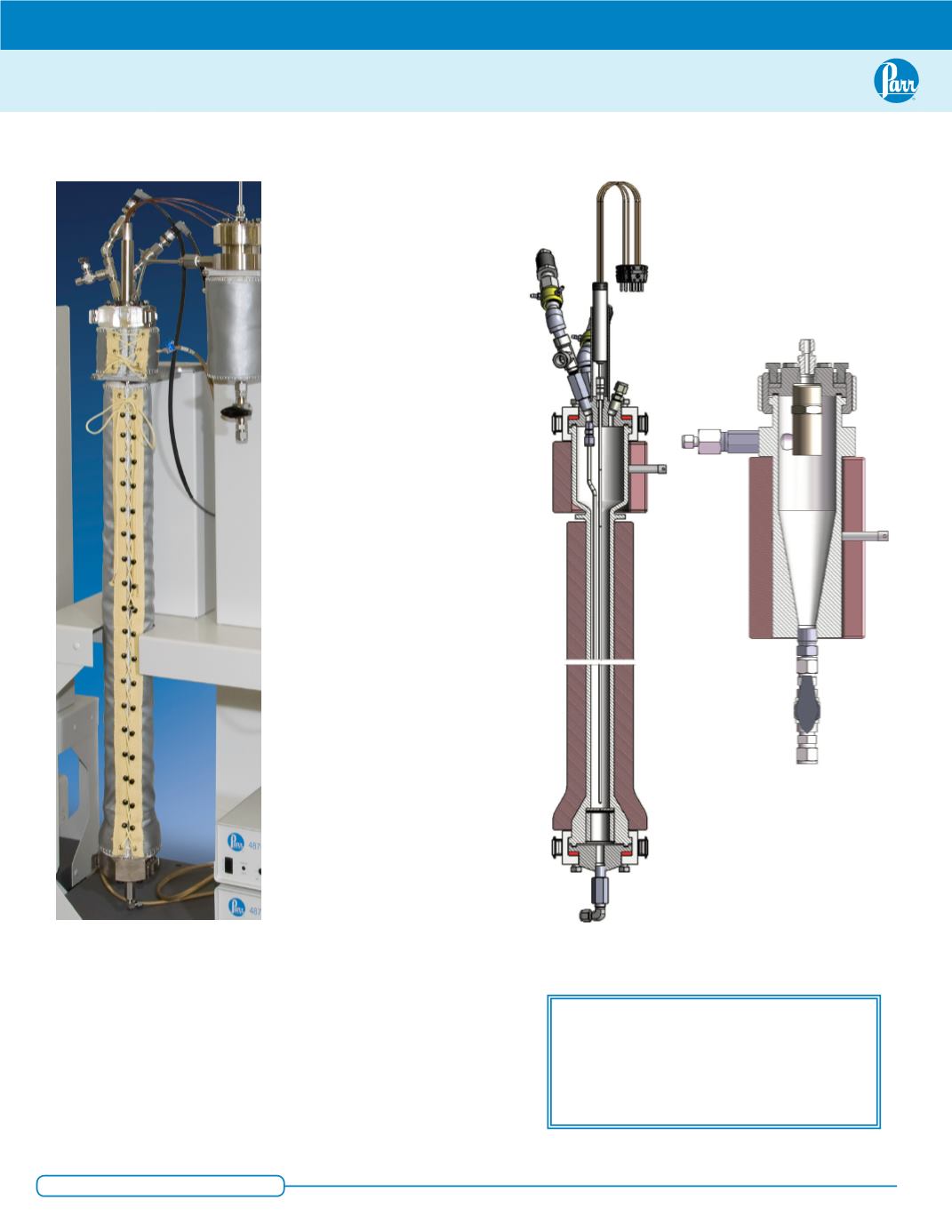

• The reactor (Diagram

1) is roughly one meter

long with a 2.5 cm ID.

The lower portion of the

reactor incorporates an

easily replaced porous

metal gas diffusion plate

and the top of the reac-

tor widens abruptly to

form a disengaging zone

for the fluidized bed.

Separate heaters are

provided for both the

main reactor and dis-

engaging zone. A mul-

tipoint thermocouple is

provided for monitoring

the internal reactor tem-

perature distribution.

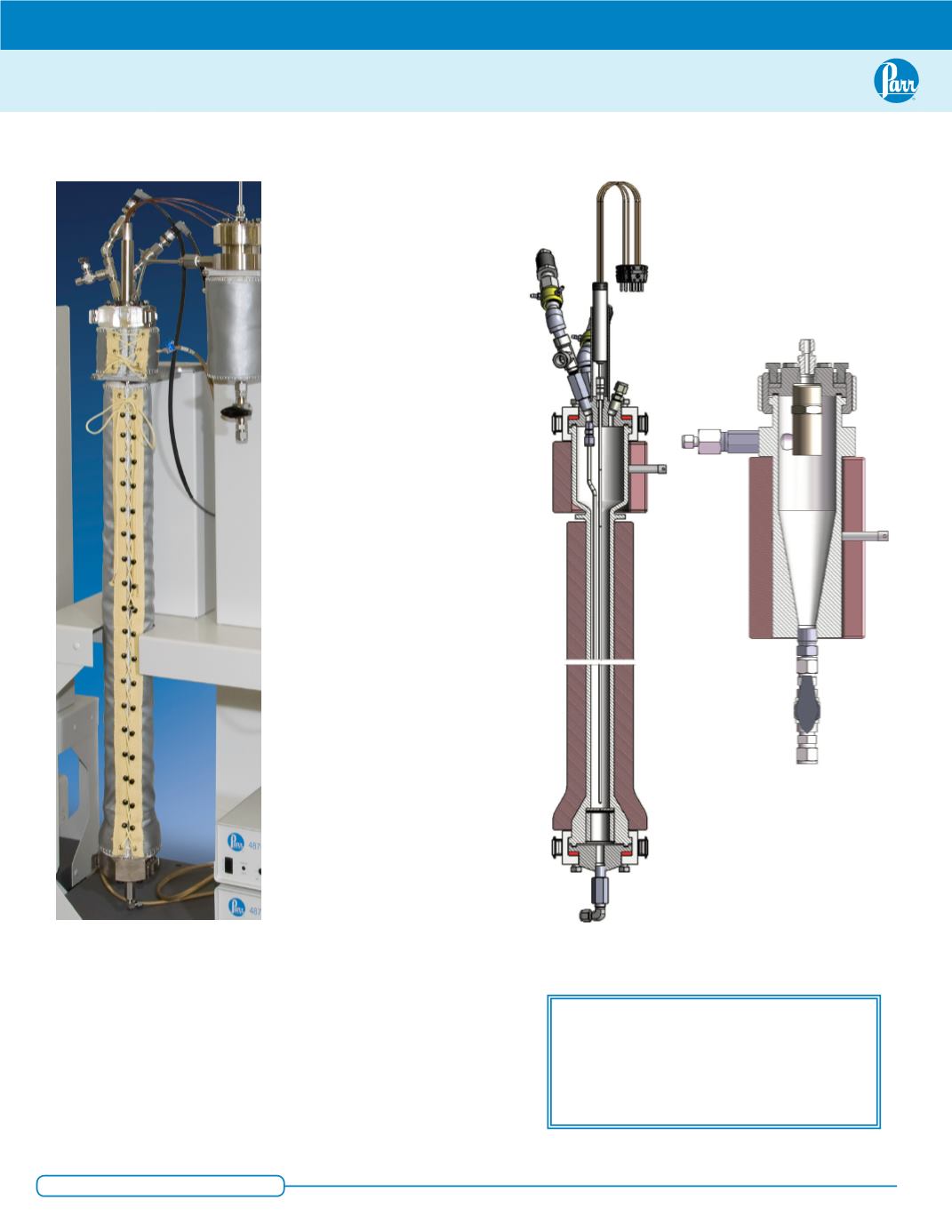

• A heated cyclone separa-

tor (Diagram 2) or filter

is provided immediately

downstream of the reac-

tor to capture the fines

resulting from particle

attrition.

Diagram 1

Diagram 2

For more information on Tubular Reactor

systems, please visit the Fluidized Bed

Reactor section of our Custom Reactor

Systems link at

• The reaction products are then cooled by a condenser

and collected in a 600 mL product receiver.

• The system pressure is maintained by a dome loaded

back pressure regulator.

• All system functions and parameters are monitored

and maintained by a Parr 4871 Process Controller.