T

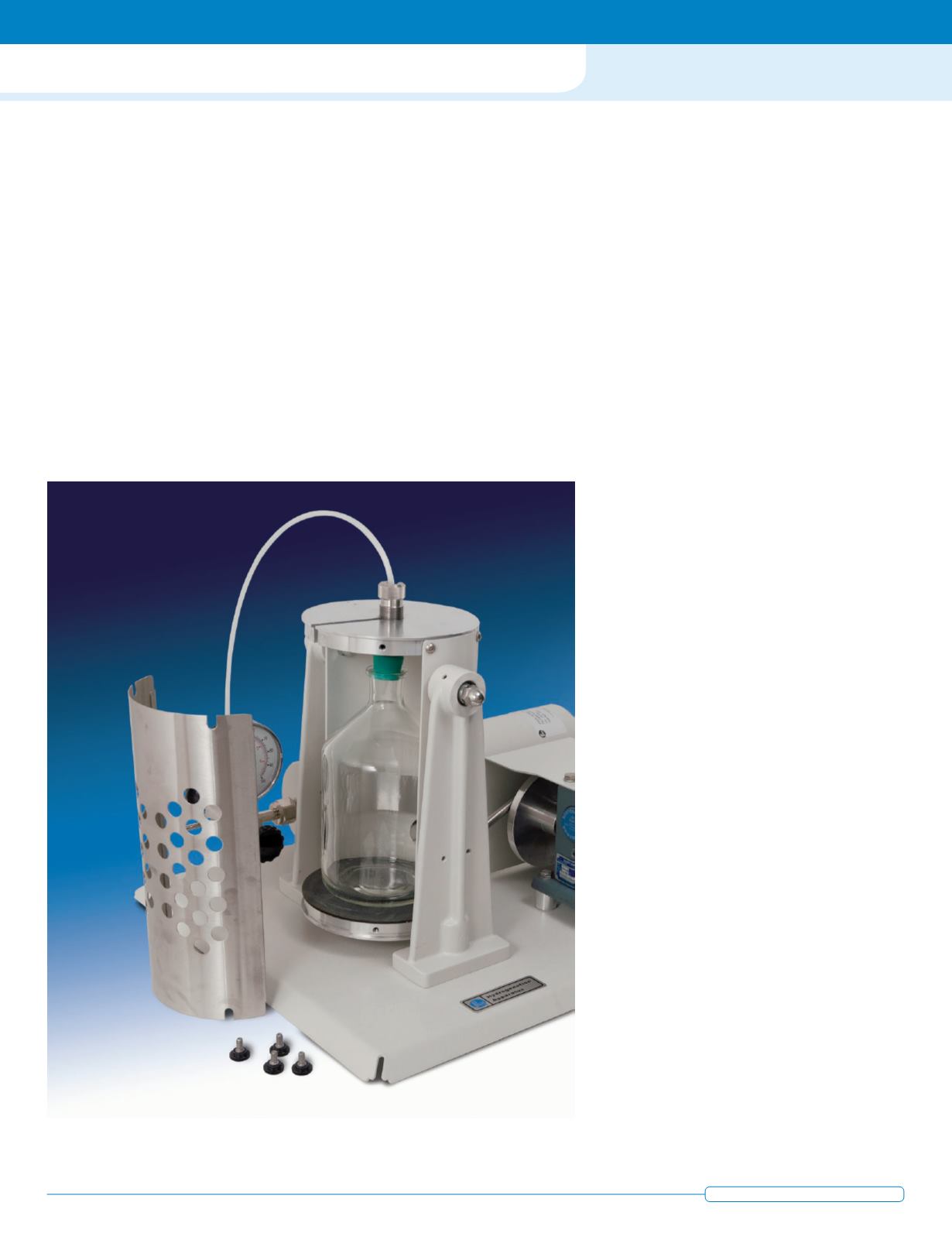

he standard 500 mL bottle (66CA) for

the 3910 Series Apparatus are made

with a heavy wall and a rounded bottom,

which reduces its actual capacity to about

470 mL. This bottle fits tightly inside

a wrap around metal screen that will

restrain flying glass in case of accidental

breakage. Smaller charges can be treated

in an alternate 250 mL bottle (66CA2)

which fits into the same bottle holder but

requires an additional spacer spool to

compensate for the differences in bottle

heights. Special bottles with smaller

capacities down to 50 mL or less can be

constructed for treating micro samples.

(Augustine describes a micro hydrogena-

tion bottle that can be made by sealing a

50 mL or smaller heavy walled flask inside

a larger bottle.)

Bottles for the larger 3920 Series

Apparatus are made in several sizes from

1000 to 2250 mL all of which fit into the

same bottle holder. One each of the plain

1000 and 2000 mL bottles is furnished

with each 3920 Series Hydrogenator.

These are carefully selected, machine

blown bottles which, because of their

large size, are restricted to 40 and 30 psig

working pressures. If higher pressures up

to 60 psig are required for treating large

amounts of reactants, users are urged to

purchase the special 2250 mL heavy duty

bottle (72CA4) which is made specifically

for this purpose. This is a hand blown,

borosilicate glass bottle with an extra

heavy wall that is much stronger than

the standard machine-made bottles. Or,

for reactions that can be handled satis-

factorily in stainless steel, there is a 1825

mL bottle made of T316 Stainless Steel,

which can be installed in any 3920 Series

Apparatus. This bottle with a stainless

steel cover and O-ring seal will withstand

working pressures up to 65 psig.

Safety Considerations

P

arr Shaker Type Hydrogenators are

usually operated in an open labora-

tory without additional barricades or

protective screens, but the operator must

realize that additional protection may be

necessary if there is any possibility that

a reaction may run out of control, or if

unexpected bottle breakage would pro-

duce a hazardous spill of toxic or flamma-

ble materials. Potentially explosive reac-

tions are best handled with the apparatus

located behind a suitable barricade or in a

pressure test cell.

There must be no gas burners or open

flames near a hydrogenation apparatus.

The room must be well ventilated and any

gas released from the apparatus should

be discharged into an explosion proof

Bottle Clamp for 3921 Apparatus with Guard Screen Removed.

Shaker Type Hydrogenation Apparatus

P a r r I n s t r u m e n t C o m p a n y

6

w w w . p a r r i n s t . c o m