Custom Modifications

Most cell disruption procedures can be handled readily in the

920 mL, 4635 Vessel with its customary fittings and attachments,

yet applications may arise in which it will be desirable to modify

a vessel to meet special requirements. If initial studies show a

need for modifications, the user can return any vessel to the

factory for such changes or additions as may be needed.

Changes sometimes requested include:

Multiple sample capacity.

Up to three additional dip tubes

and discharge valves can be installed in any vessel (except the

45 mL size). With these additional outlets and appropriate sample

holders, as many as four samples can be processed indepen-

dently and simultaneously in a single unit.

Special valves.

Valves with either larger or smaller orifices

can be provided. Users processing large quantities of materials

that have a tendency to plug the orifice of the standard throttling

valve may want to substitute either a larger needle valve or

a ball valve to permit faster flow rates or to avoid stoppage.

Fine metering valves with smaller orifices and very precise

control capabilities may be helpful when treating samples that

must be processed under very exact and repeatable conditions.

Such valves may also be desirable when working with very

small samples.

Size conversion.

Since cylinders for the 920 and 1850 mL

vessels are interchangeable and both vessels use the same head

and closure, any user of a 4635 Vessel can increase the capacity

of his unit to the 4636 size by simply purchasing a deeper

cylinder (599HC22) and a longer dip tube (592HC5). A similar

conversion can also be made from the one gallon vessel to the

two gallon size for users interested in vaccine production or in

similar large volume applications. These larger vessels can also

be equipped with vigorous internal agitators to speed equilibrium

times when processing large volumes of material.

Inquiries concerning any of these modifications should be

directed to Parr Instrument Company Customer Service.

Easy Access To Vessel Chamber

Each of these vessels, except the small 45 mL size, has a split-

ring closure – an exclusive Parr design which allows the vessel to

be opened or closed easily without disturbing any of the fittings

or connecting lines attached to the head. In this closure two ring

sections slide into place from the sides of the vessel to lock the

head in position while a self-sealing O-ring maintains a tight seal

at all pressures. The ring sections are secured by a latch mech-

anism that is connected to the split rings.

On the small, 45 mL vessel, a firm closure is obtained by

simply turning down a knurled cap until it is hand tight. No

wrenches or fixtures are required.

Safety Protection

All Parr Cell Disruption Vessels are designed to accommodate

a commercial nitrogen cylinder. The 920 mL and 1850 mL vessels

are protected by a safety rupture disc which will burst at approxi-

mately 3000 psig, well below the pressure at which any parts

of the vessel would fail. The 1 and 2 Gallon O-ring vessels are

protected by 2200 psig rupture disc to protect the assembly as

this is the maximum allowable working pressure for its compo-

nents. The flat gasket seal version of the 1 and 2 Gallon is rated

at 1900 psig and is protected by a rupture disc of the same rating.

A 3000 psi pressure gage is standard, but other gages as well as

rupture discs with lower pressure ratings can be furnished on

special order. The 45 mL does not include any additional safety

devices and is rated for a maximum 2900 psig for use with a

full nitrogen tank.

Includes Nitrogen Filling Connection

An 1831 Nitrogen Filling Connection furnished with each

vessel provides all of the fittings needed to fill the vessel from a

commercial nitrogen cylinder. The 1831 Connection consists of a

control valve with a standard CGA-580 coupling for attachment

to a nitrogen cylinder, a tank pressure gage and a flexible Nylon

pressure hose for connection to the vessel inlet valve. Extra

O-rings for the vessel head are included with each vessel.

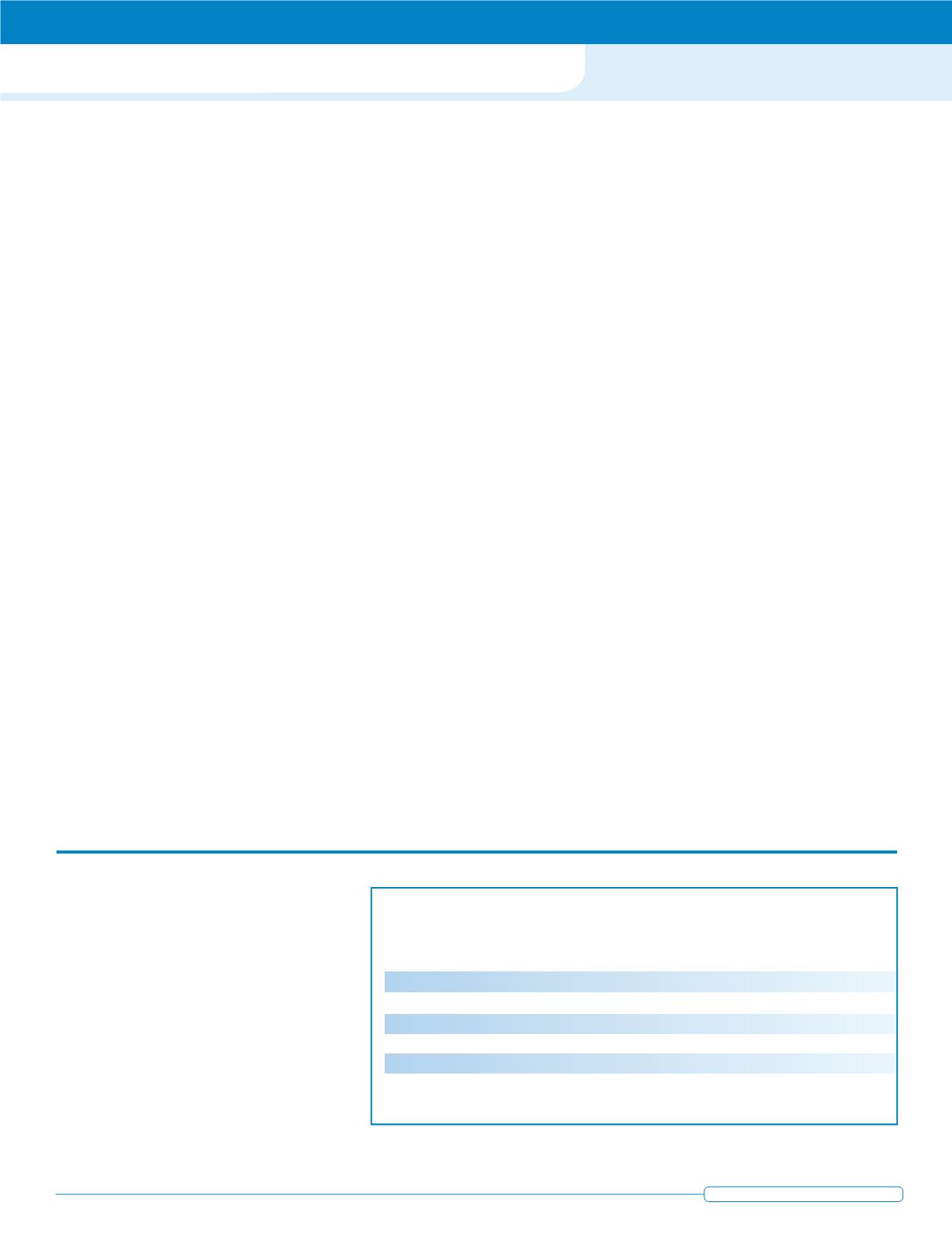

Ordering

Information

Orders for these vessels should specify

the catalog number and internal volume

of the vessel as shown in the following

table. Each vessel will be made of an AISI

300-series stainless steel and equipped

with a 0-3000 psi pressure gage and 1831

Nitrogen Filling Connection, unless other

construction and other fittings are specified.

Parr Cell Disruption Vessels

Inside

Inside

Catalog Internal

Maximum Maximum Working Diameter

Depth

Number Volume Sample Size Pressure, psig (bar)

Inches

Inches

4639

45 mL

30 mL

2900* (200)

1.50

2.25

4635

920 mL 600 mL

3000 (200)

3.75

5.10

4636

1850 mL 1200 mL

3000 (200)

3.75

10.10

4637**

1 gallon 2.5 liters

2200 (152)

6.00

8.60

4638**

2 gallon 5.0 liters

2200 (152)

6.00

17.20

* MAWP of 2900 psig is intended for maximum pressure of nitrogen fill tank

** O-ring only. Optional flat gasket design rates 1900 psi MAWP.

P a r r I n s t r u m e n t C o m p a n y

4

w w w . p a r r i n s t . c o m

Cell Disruption Vessels