O

perating procedures for the Parr Cell Disruption Vessel

can be adjusted to suit individual requirements. The

procedures described here will be suitable for most

applications, but they are not intended to be either complete or

restrictive. Each operator will develop refinements which produce

the best results with his particular materials, while still observing

the basic vessel handling instructions and safety precautions

described below.

Preparing The Cell Suspension

Individual cells such as lymphocytes, leukocytes, tissue culture

cells or very fragile bacterial cells will not require pretreatment.

Tissues must usually be preminced to ensure that they will

pass through the dip tube and discharge valve. Hand presses,

mechanical homogenizers, pressing through screens or sieves,

slow speed blenders and manual dissection have all been used

successfully for this purpose. Tougher tissues will require finer

premincing than will softer tissues. Best results will be obtained

if any connective tissue which might block or plug the discharge

passages are removed or finely divided at this time.

The intended use of a homogenate generally determines the

composition of the suspending medium. Isotonic solutions are

commonly used. Solutions with higher concentrations will tend to

stabilize the nucleus and organelles. Conversely, very dilute solu-

tions will prestretch the cells by osmotic pressure and will render

them more susceptible to disruption by the disruption method.

Several investigators have reported that very small quantities

of calcium chloride, magnesium acetate, or magnesium chloride

added to the suspending medium will stabilize the nuclei when

differential rupture is desired. Ratios of approximately 10 mL of

suspending medium to one gram of wet cells are commonly

used to prepare the cell suspension. Higher or lower ratios can

also be used.

Charging The Vessel

Instead of pouring the cell suspension directly into the vessel

cylinder, most users will find it convenient to hold the sample

in a beaker or test tube which can be placed inside the larger

vessels. A supplementary container is particularly useful when

working with small samples. As a general rule, the capacity of

the inner container should be approximately twice the volume

of the suspension to be treated. Larger samples may, of course,

be poured directly into the cylinder. If an inner container is used,

it must be positioned so that the dip tube leading to the release

valve reaches to the very bottom of the container. Plastic test

tubes, centrifuge tubes and beakers work well as auxiliary sample

holders. They are not only unbreakable but they also can be

floated on ice water within the vessel to keep the suspension cool

during equilibration and to bring the bottom of the sample holder

up to the tip of the dip tube to ensure complete sample recovery.

Sealing and Pressurizing The Vessel

After placing the cell suspension in the vessel, set the head on

the cylinder with the dip tube extending into the sample holder

and attach the split ring clamp. No wrenches, holders or special

tools are needed in this closing operation. The two ring sections

slide together from either side of the vessel and latch into place.

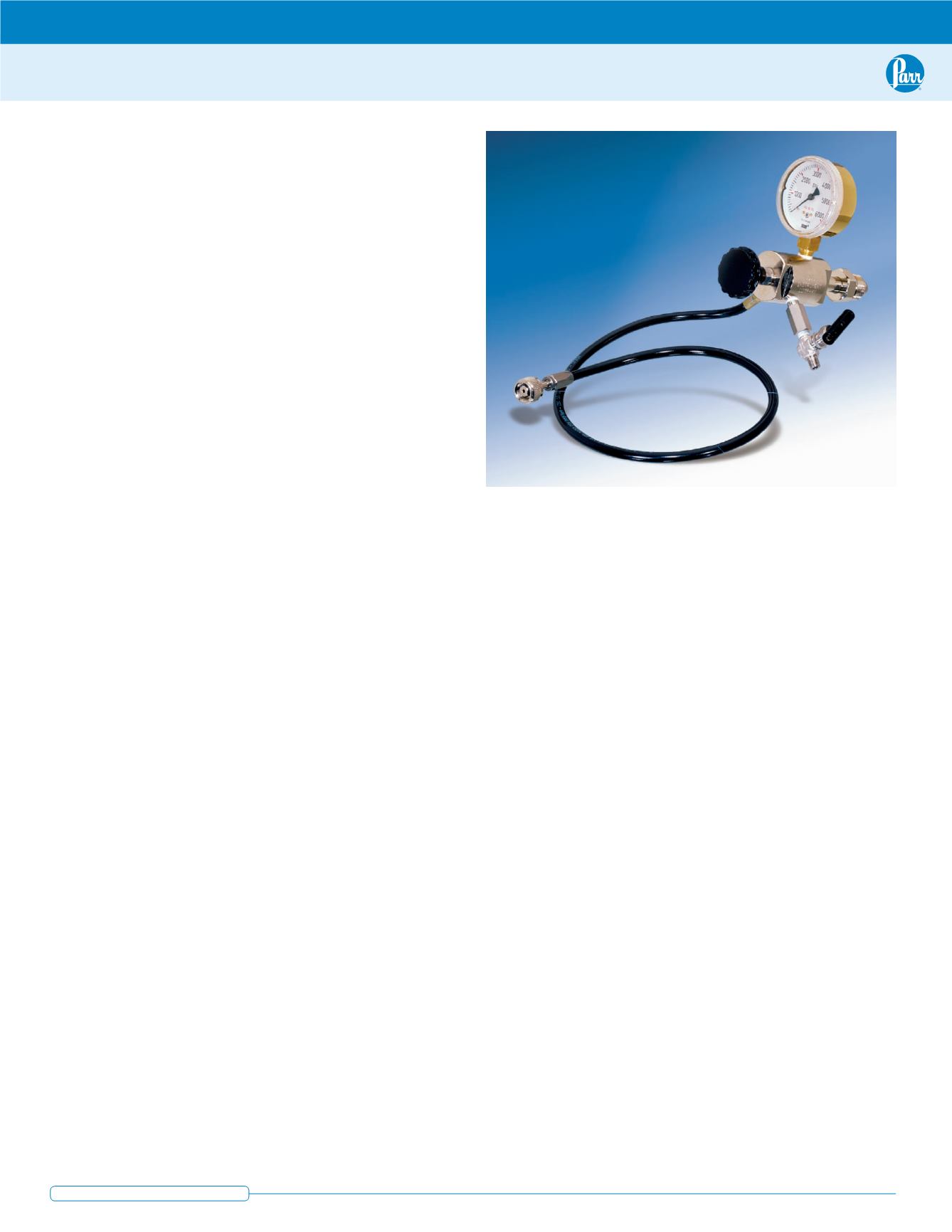

To pressurize the vessel, attach the filling connection to a

commercial nitrogen cylinder and connect the flexible Nylon

pressure hose to the vessel inlet valve. A quick disconnect fitting

on the hose makes it easy to complete this connection and to

remove the vessel from the filling system after pressure has been

applied. A gage on the filling connection shows the pressure in

the supply cylinder while a gage on the vessel head shows the

pressure applied to the sample.

It should be noted that the vessel does not have to remain at

a fixed location during the loading, closing and filling operations.

These steps can be performed anywhere in the laboratory and

the vessel can then be carried to a different location for pressure

equilibration and sample recovery if the user wishes to do so.

The amount of pressure used will vary with different samples

and with different disruption or homogenization procedures.

Large samples will often absorb a significant amount of nitrogen,

making it necessary to re-pressurize the vessel one or more times

in order to maintain the desired pressure level. Also, a significant

pressure drop may occur as the homogenate is released from the

vessel, making it necessary to add additional nitrogen in order to

treat all of the sample at the same pressure level. Such additions

can be made easily using the control valves provided on

the vessel head and on the filling connection.

Operating Procedures

1831 Nitrogen Filling Connection

B u l l e t i n 4 6 3 5

5

1 - 8 0 0 - 8 7 2 - 7 7 2 0

C e l l D i s r u p t i o n V e s s e l s