4

Parr Instrument

Acid Digestion Bombs

potentially hazardous samples. Each of these bombs has a thick-

walled Teflon liner which completely isolates the charge from the

supporting body. These liners are removable and can be charged

or emptied while outside of the bomb to eliminate any possible

contamination from acid contact with metal parts. They can be

replaced if they become damaged or contaminated.

UNIQUE CLOSURES

Several designs are used to keep Parr acid digestion bombs

tightly sealed during consecutive heating and cooling cycles when

conventional seals might leak. One of these designs uses a

tapered closure between the Teflon cup and cover with an

unusually long sealing face which tends to become self-sealing.

This long path also minimizes the tendency for acid migration

through the joint. Bombs using this design can be sealed by

simply turning down a knurled cap by hand without using a

wrench or spanner. For applications requiring higher temperatures

and pressures, the Teflon lines are made with a broad, flanged

closure and sealed by tightening the bomb cap with a spanner or,

in a larger design, by using cap screws to develop the sealing

force. Tight closures for the Teflon cup in Parr microwave bombs

are developed and maintained with self-sealing Teflon O-rings.

SPRING-LOADED SEALS

Since Teflon has a much larger coefficient of thermal

expansion than the materials within which a liner is enclosed, a

Teflon liner will expand and contract more than its enclosure

when these bombs are heated and cooled. To compensate for this

difference and to maintain a constant loading on the Teflon seal,

all Parr acid digestion bombs have spring-loaded closures which

will continue to maintain pressure on the liner seal throughout

the operating cycle, and particularly during cooling when Teflon

parts would otherwise relax and leak.

SAFETY RUPTURE DISCS

Safety rupture discs are provided in most Parr acid digestion

bombs to protect the bomb and the operator from the hazards of

unexpected or dangerously high internal pressures. The burst

pressure in each installation is established by a frangible metal

disc installed as a sandwich with a matching inner disc which

serves as a corrosion barrier to protect the rupture disc from

corrosive vapor.

METAL JACKETED AND

MICROWAVE STYLES

Parr Teflon-lined acid digestion bombs are made in two

different styles: There is a line of metal-jacketed bombs which

can be heated in an oven, sand bath, oil or water bath and in

other conventional ways, and a new line of digestion bombs

developed specifically for rapid heating in a microwave oven.

Both styles are made in several sizes, offering a broad selection

of bombs ranging from economical models for routine tests to

massive styles for procedures involving extreme conditions or

Bulletin 4700

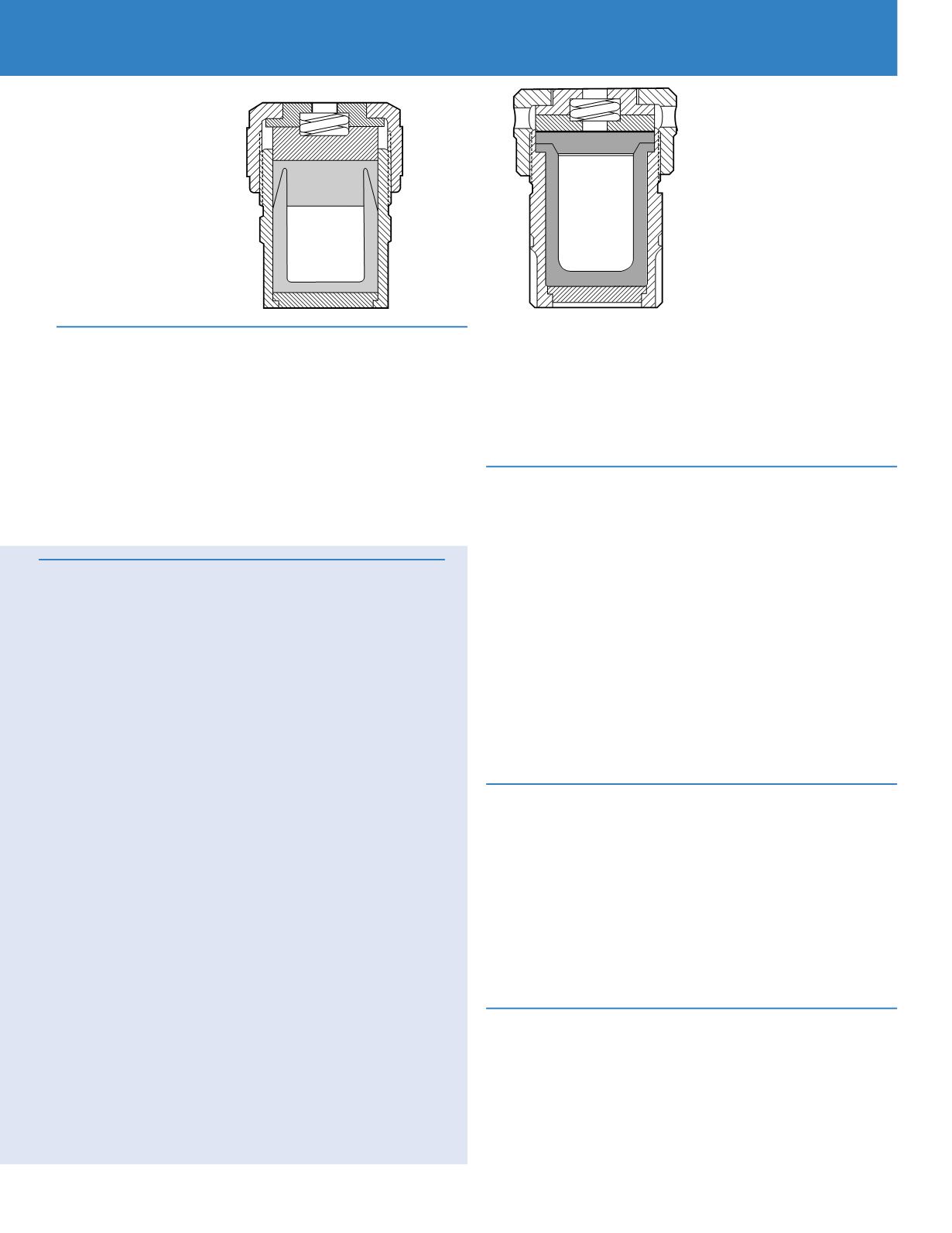

The 4745 Bomb uses an

A255AC Teflon liner with a

long, tapered closure.

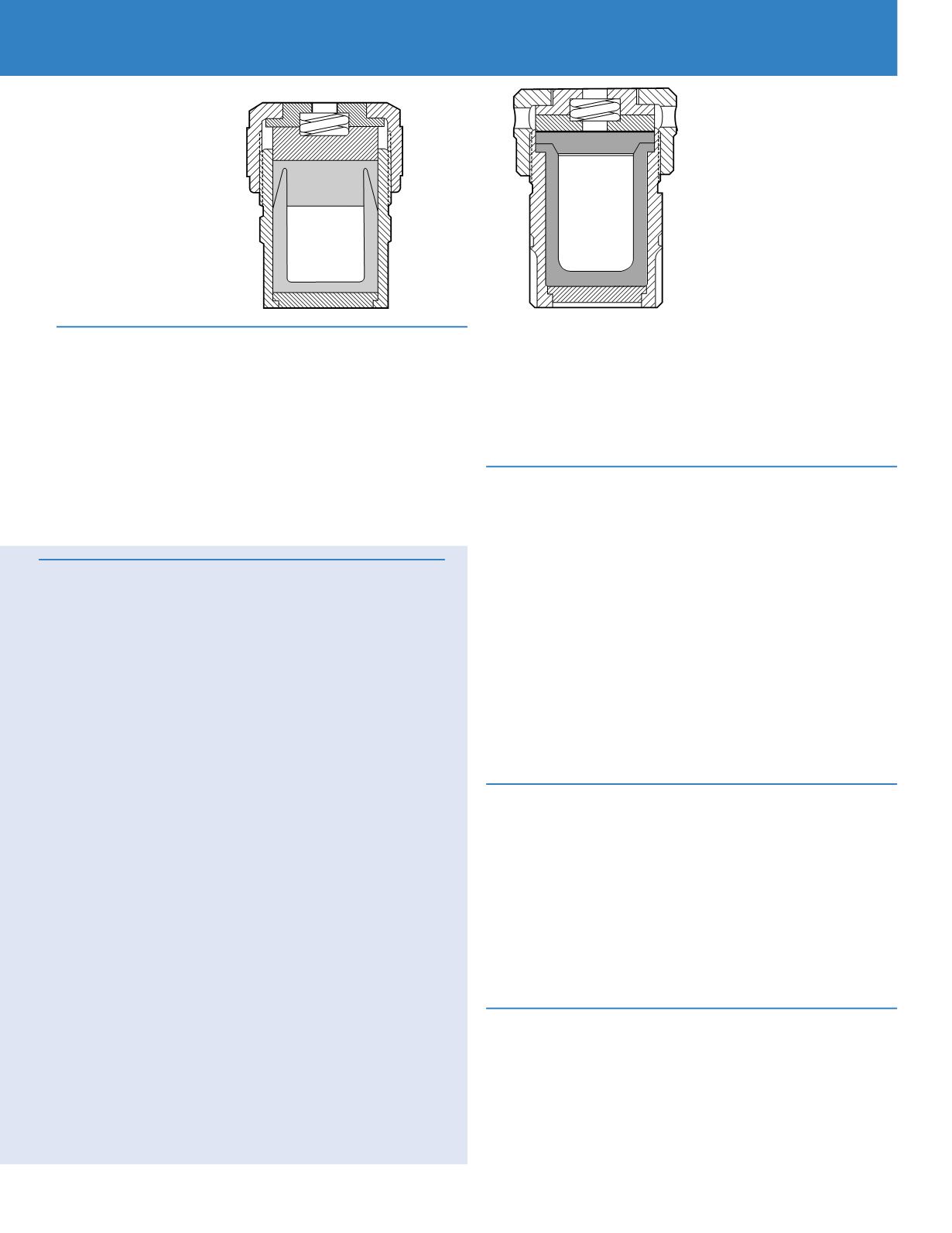

The 4749 Bomb uses an

A280AC Teflon liner with a

flanged closure.

THE NATURE OF TEFLON

The use of Teflon for the sample cup in these bombs is an obvious

choice, not only because of its unique inertness to strong acids and

high temperatures, but also because it is transparent to microwave

energy, allowing energy to flow directly to the sample while serving

also as an insulator to restrict heat flow from the reaction zone. Teflon

does, however, have two characteristics which make it somewhat less

than perfect for this application, and the user who understands these

deficiencies will be able to minimize their effect upon his work.

First, Teflon has a tendency to creep or flow under pressure or load.

This tendency is present even at room temperature and it is

accentuated at higher temperatures. At temperatures below 150 °C the

tendency to creep will be negligible. But as temperatures rise above

150 °C the creep effect will become more pronounced, making it more

difficult to maintain tight seals and resulting in deformation and

shorter life for the Teflon components. The extent of the creep effect

will be roughly proportional to the maximum operating temperature.

Secondly, Teflon is a porous material. Although the materials and

designs used in Parr acid digestion bombs minimize the effects of this

porosity, users of these bombs can expect to see evidence of vapor

migration across the cover seal and through the wall of the liner itself.

Parr is able to minimize these problems by machining these parts from

virgin Teflon which has been molded at an optimum pressure selected

to reduce any porosity to an absolute minimum. The thick walls and

effective seals used in these bombs also help to overcome these

undesirable properties. Experiments have shown that the amount of

solute lost in this manner during a normal digestion is negligible,

but vapor migration into the walls of the Teflon cup will occur and

cannot be avoided.