A

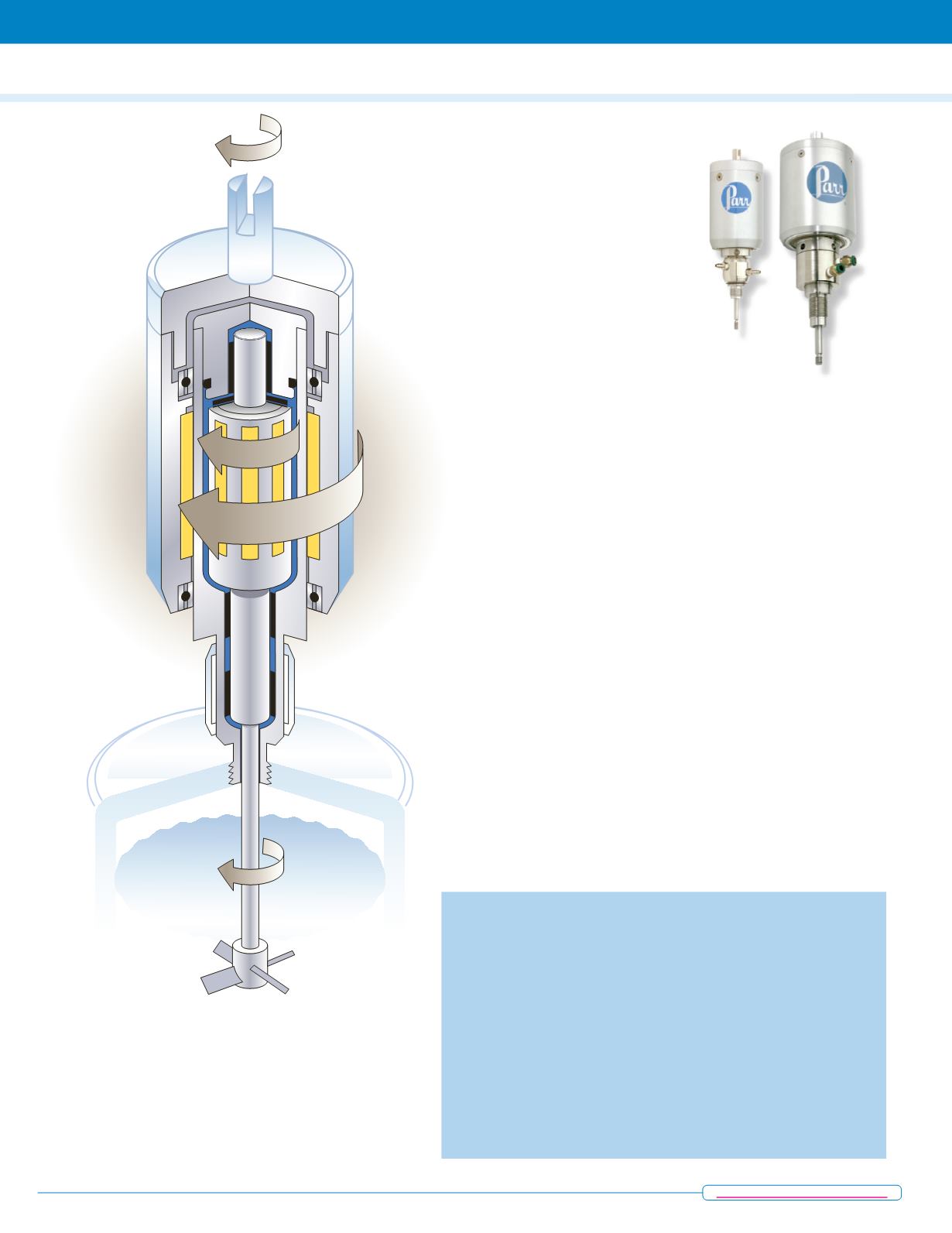

ll Parr stirred reactors are

equipped with a magnetic

drive to provide a trouble-free

linkage to an internal stirrer,

thereby avoiding the leakage

problems which can arise with a

packed gland stirrer drive. With

a Parr magnetic drive there are

no rotating seals. The drive turns

freely and the system remains

gas-tight, permitting long,

continuous runs at pressures up

to 5000 psi (345 bar) with little

or no attention to the seal and

drive.

Parr drives are assembled

with specially designed per-

manent magnets which have

excellent temperature stability

and can be depended upon to

operate for long periods with

little or no flux degradation.

Magnets for the inner rotor to

which the stirrer shaft is attached

are enclosed in a stainless steel

(or other alloy) housing, perma-

nently sealed by laser welding

and supported by graphite-filled,

PTFE bushings to provide a long

life, chemically inert stirring

system. Magnets for the outer

drive are also fully enclosed and

supported by twin, high quality

sealed ball bearings for smooth

operation and long life. A water

cooling sleeve attached to each

drive protects the components

from excessive heat arising from

the reactor.

Significant progress was made in recent years in both magnetic

materials and magnetic coupling design. Parr uses neodymium-iron-

boron magnets with 25% more coupling force than samarium-cobalt

magnets. With very few exceptions involving gear reduction drives,

the magnetic stirrers fitted to reactors have higher coupling torques

than the stall conditions of standard motors. Today magnetic drives

are used with confidence for high viscosity polymerization reactions.

Parr magnetic drives are supported with three graphite-filled

PTFE bushings and quality internal ball bearings. They routinely deliver

2000 hours of operation without service.

Four Sizes

Parr magnetic drives are

made in four sizes, designed to

match the full range of Parr reac-

tor sizes and to provide alternate

drives for high viscosity loads,

higher stirring speeds and other

special requirements. Each drive

is assembled in a sealed housing

which threads directly into the

reactor head.

The A1120HC and A1180HC

models are the standard units

normally furnished with the

reactor sizes listed in the adjoin-

ing table. The A1750HC2 model

is a special high torque drive

intended primarily for heavy

loads and high viscosity applica-

tions. When it is used to replace

a standard drive, the standard

motor and drive system may

have to be modified to provide

the higher torque which the

A1750HC2 drive is capable of

transmitting.

14

P a r r I n s t r u m e n t C o m p a n y

High Torque Magnetic Drives