T

here are four different types

of gasketing material for the

main head seal in Parr reactors

and pressure vessels, each

with its own advantages and

limitations. Some of these are

recent additions which have sig-

nificantly expanded the choices a

user can consider when selecting

a closure and gasket material

for the intended operating

conditions.

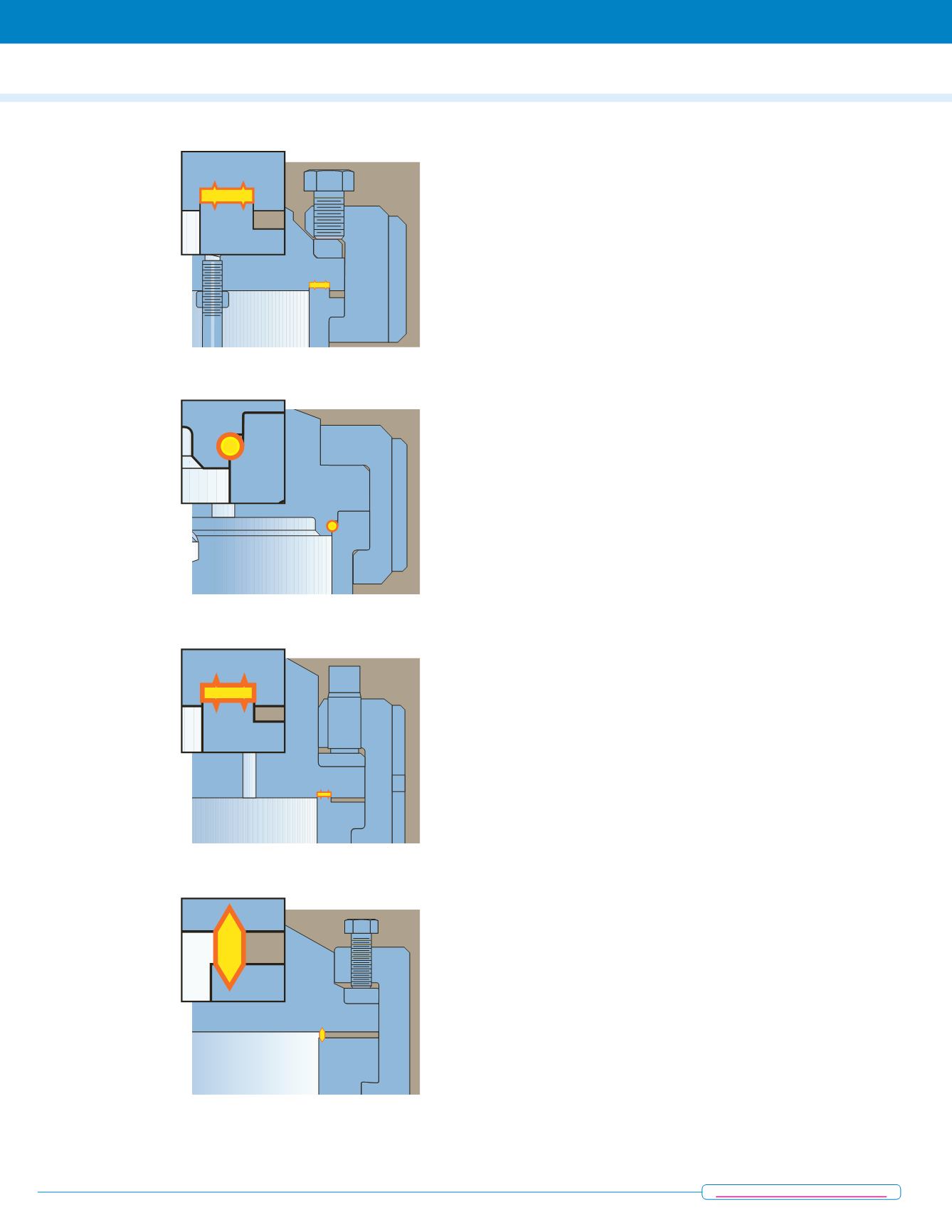

Confined and Contained

Flat PTFE Gaskets for

Temperatures to 350 °C

The traditional and most

popular main head gasket for

Parr vessels is a flat gasket made

of a PTFE fluoropolymer. In Parr

flat gasket closures, the gasket

is held in a recess in the vessel

cover. The mating lip on the cyl-

inder closes the recess, leaving

the gasket completely confined

with only a small inside edge

exposed to the reactants within

the vessel. This combination of

complete gasket containment

and the exceptional properties

of PTFE materials produces a

reliable closure for working

temperatures up to 350 °C.

Flat contained gaskets require

an initial loading pressure in

order to develop and to maintain

a tight seal. In Parr designs this

is produced by tightening a ring

of cap screws in a split-ring

cover clamp. Fortunately PTFE

is slightly “plastic” and will flow

under pressure, producing a seal

that improves with each use as

the gasket is forced into the faces

on the head and cylinder. It also

is a very forgiving seal which

does not require the special care

needed to achieve a uniform

loading, which is essential when

working with a metal or other

non-plastic gasket material.

An equally important advan-

tage of the PTFE gaskets is their

essentially universal chemical

resistance.

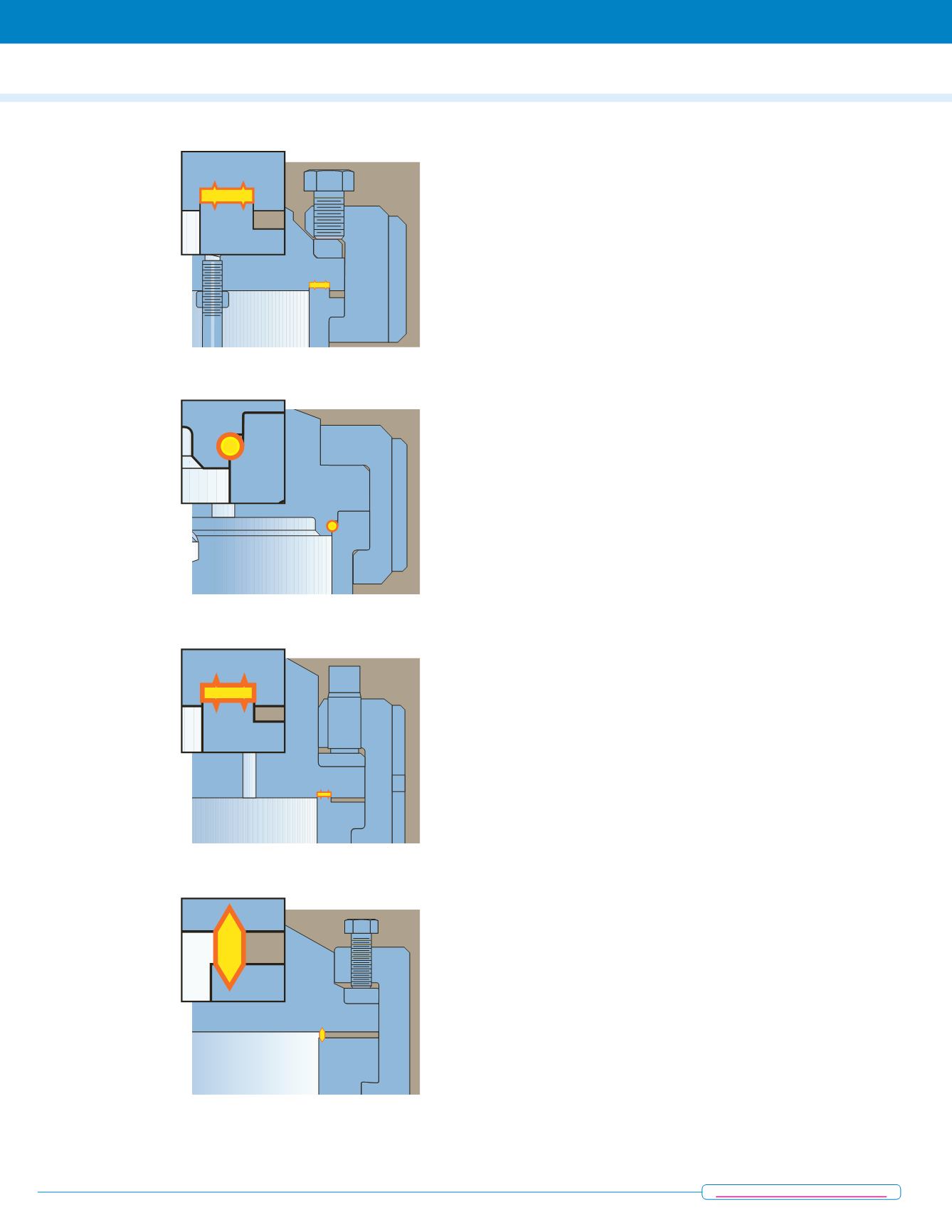

Self-Sealing O-rings

Parr has greatly expanded its

offerings of reactors and vessels

which feature self-sealing O-ring

closures. In these designs the

sealing force on the gasket is

developed from pressure within

the vessel itself, eliminating the

need for cap screws in the split

ring to pre-load the seal. In these

self-sealing closures the split ring

sections simply lock the head

and cylinder together.

Users who select the self seal-

ing O-ring design must consider

two important characteristics

of elastometric materials. First,

they will not withstand operating

temperatures as high as the PTFE

gaskets. Secondly, none of these

materials offers the universal

chemical resistance of PTFE poly-

mers. The chemical resistance

is especially important since the

O-ring is directly exposed to the

contents of the vessel.

Although there are a number

of available O-ring materials, the

real choice comes down to two.

Fluoroelastomer (FKM) O-rings,

such as Viton, are a first choice

for Parr self-sealing closures.

They have good chemical resis-

tance and a working temperature

up to 225 °C. Perfluoroelastomer

(FFKM) O-rings, such as Kalrez,

have extremely broad chemical

resistance and can be used at

working temperatures up to 275

°C. Unfortunately, this material

Flat PTFE Gasket

O-ring FKM Seal

High Pressure Metal Gasket

Flat Flexible Graphite Gasket

18

P a r r I n s t r u m e n t C o m p a n y

Gasket and Seals