26

P a r r I n s t r u m e n t C o m p a n y

Reactor Selection Guide

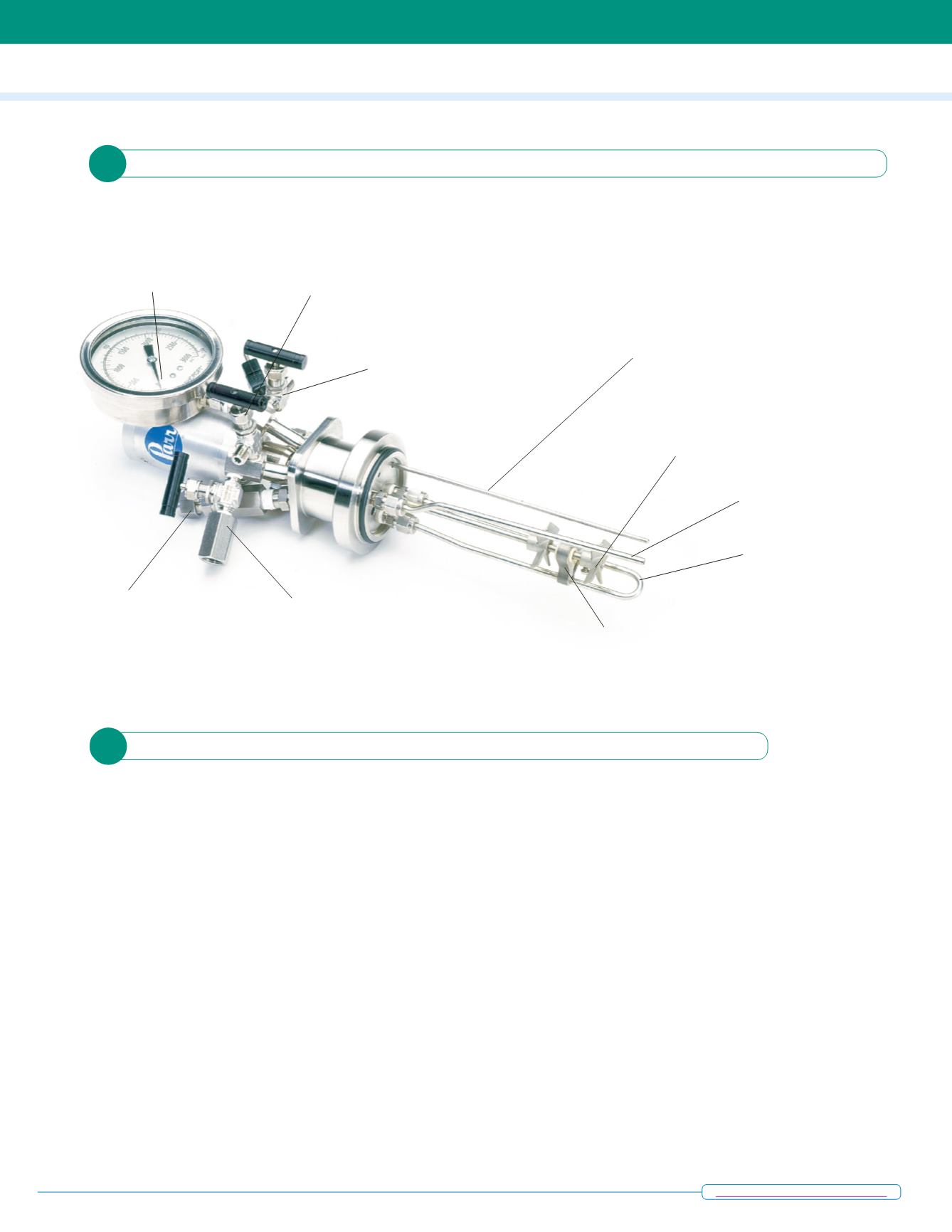

Safety Rupture Disc

to

protect the vessel and the

operator from dangerous

pressures beyond the rated

limit for the vessel.

Thermocouple or Thermowell

for measuring the temperature within the ves-

sel. In small reactors, a thermocouple encased

in a metal sheath extends directly into the

vessel. In larger reactors, and in vessels

constructed of special alloys, the control

thermocouple is inserted into a thermowell

which extends to a point near the bottom of

the vessel.

Internal Stirring System

consists of a motor drive magnetically

coupled to an internal stirrer shaft with

attached turbine-type impeller(s).

Dip Tube

Cooling Coil

Pressure Gage

, analog type,

which shows the pressure

within the vessel at all times.

Gas Release Valve

to release

gas from the reactor during or

at the completion of a run.

Guide or Foot Bearing

with a PTFE bushing

to support and stabilize lower stirrer shaft. (Not

required with footless magnetic drive)

Liquid Sampling Valve

for

withdrawing liquid samples

through the dip tube shared with

the gas inlet valve. Incoming gas

can be used to clear the dip tube

between liquid samples.

Gas Inlet Valve

for charging gas

into the reactor. This valve and the

liquid sampling valve are connected

to a dip tube which extends to the

bottom of the vessel.

3

Confirm Standard Fittings

T

here are a number of options to be considered and

selections to be made in order to complete the speci-

fications for a reactor. You will need to choose from the

following:

1. Sealing Style

Parr reactors may be provided with a flat gasket seal

or an O-ring seal. Most commonly, a flat PTFE gasket is

used. These are generally good for temperatures up to

350 °C. A graphite seal for temperatures up to 500 °C is

used for high temperature systems.

O-ring seals allow for a convenient, boltless closure,

but the material must be checked carefully against the

intended process as there are many solvents and gases

which attack O-rings.

2. Mounting Style

Parr reactors may be provided with a moveable vessel

mounting or fixed head mounting.

In the moveable vessel style the complete vessel

assembly (only the head in the one gallon or larger) is

removed from the heater for charging, product recovery,

and vessel cleaning.

In the fixed head style the head remains in the

mounting and the reactor heater then cylinder drop

away to open the vessel. This is useful for users who

wish to leave inlet and feed lines, discharge and vent

lines, condensers, and similar head connections undis-

turbed between runs. The head is easily removable if

desired by sliding the head out of its slot on the stand.

3. Support Stand

Parr stirred reactors are most commonly mounted on

a bench top stand for sizes of 2 liter or smaller. Vessels

1 liter or larger may be mounted on either moveable

carts or fixed floor stands. Care should be taken to check

stand dimensions with the available space at the user’s

facility.

4. Stirrer Type

Parr reactors have a magnetic drive equipped for

most low viscosity fluids and light slurries. Drives with

4

Specify Detailed Options