Jacket Designs

Sample

Fired

Controlled

Jacket

Calorimeter

Temperature

Time

P

arr Series 6000 Oxygen Bomb Calorimeters described in this brochure feature a high degree

of automation with touch screen operation, Linux operating system and fifth generation

microprocessor control.

Sample

Fired

Measured

Jacket

Calorimeter

Temperature

Time

Calculated

Jacket

Calorimeter

Temperature

Time

Sample

Fired

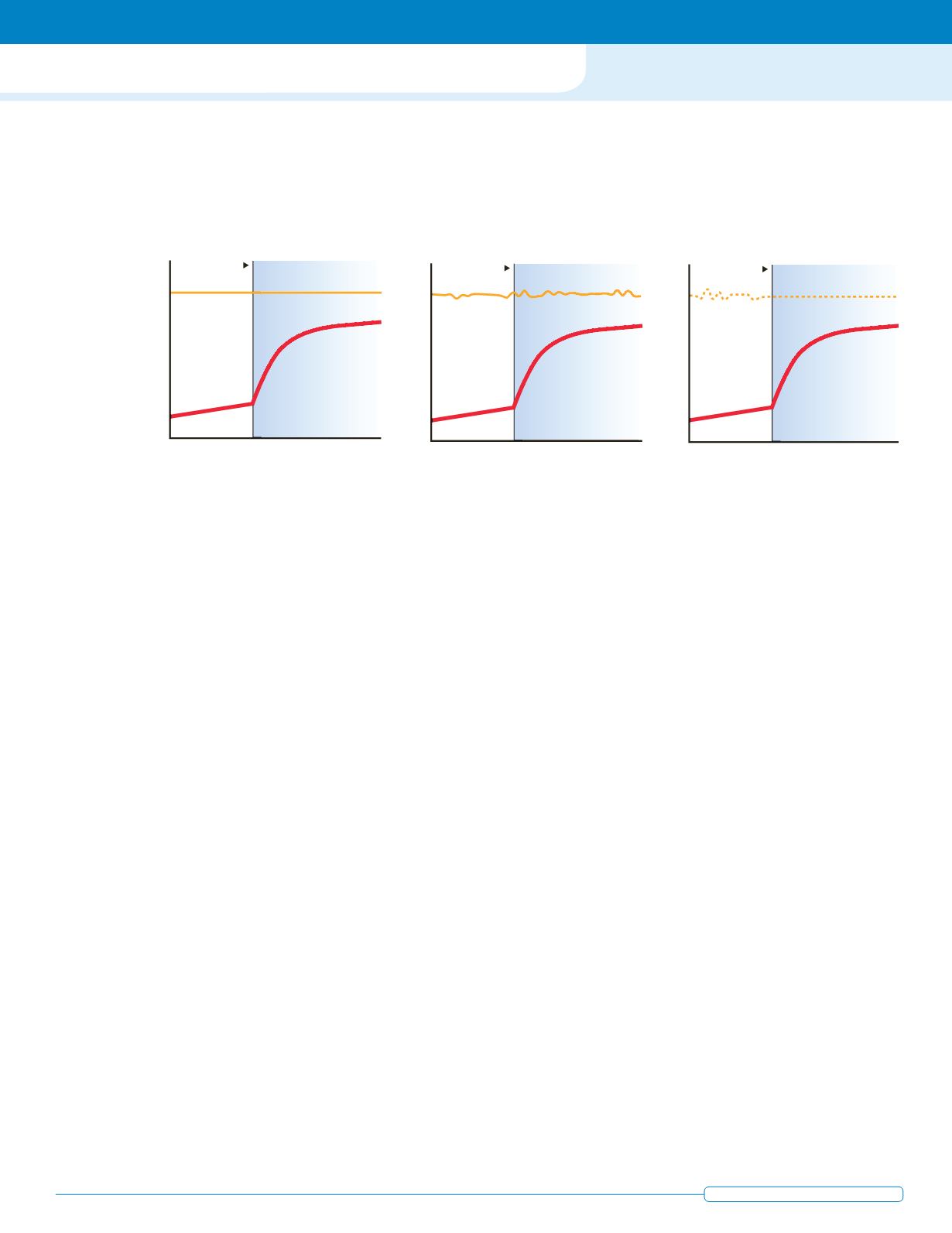

Isoperibol Calorimetry

An isoperibol calorimeter is one

where the surrounding jacket is

maintained at a constant tem-

perature while the temperature

of the bomb and bucket rise as

heat is released by the combus-

tion. The Model 6400 and 6200

Calorimeters are true isoperibol

calorimeters. In these implemen-

tations, a controlled temperature

jacket, completely surrounds

the combustion bomb and its

“bucket”. A microprocessor-

based controller monitors both

the temperature of the bucket

and the jacket and performs the

necessary heat leak corrections

that result from differences in

these two temperatures. These

corrections are applied continu-

ously in real-time throughout

the test rather than as a final

correction based on pre and

post test measurements.

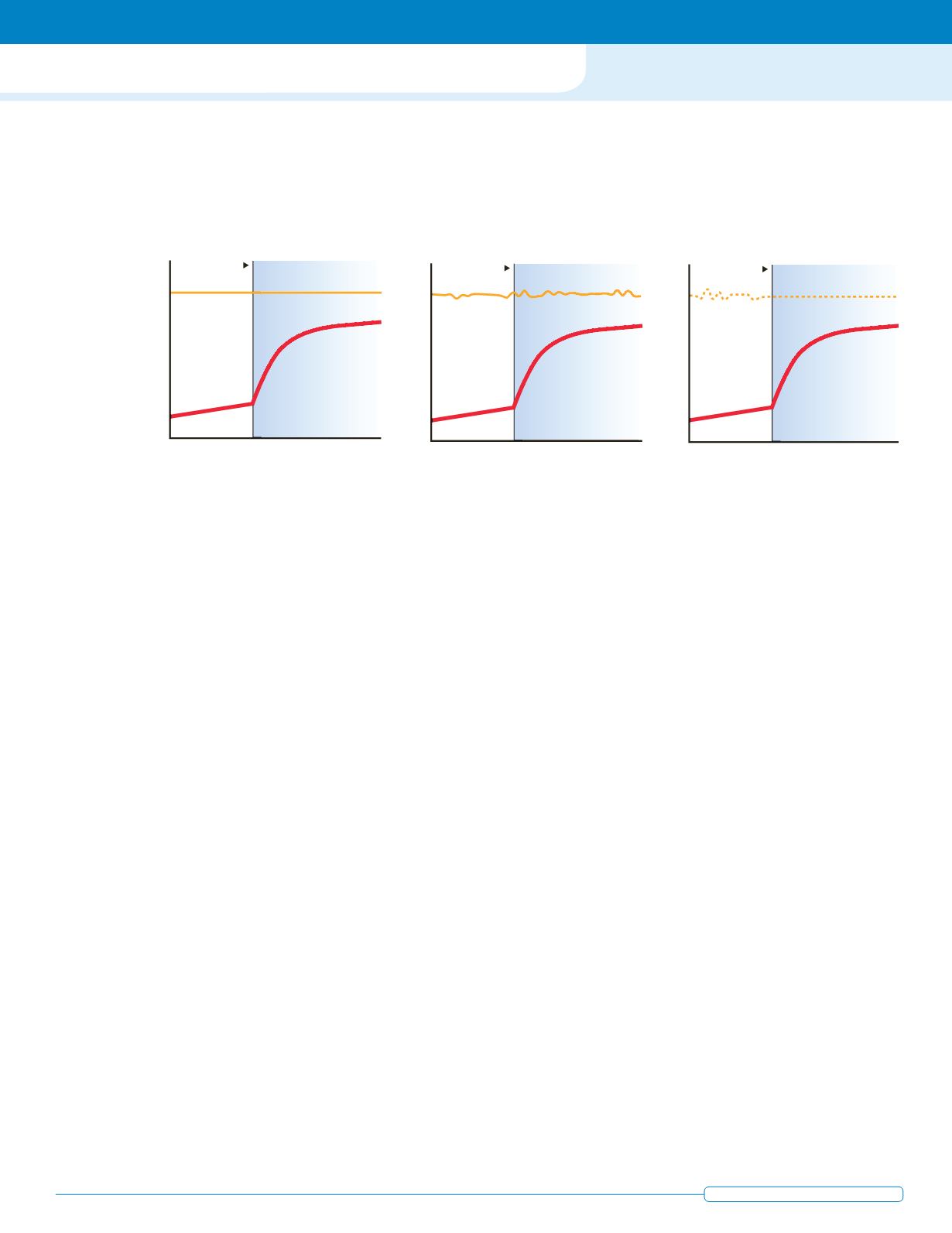

Continuously Compensated

Calorimetry

The Parr 6100 Calorimeter

takes advantage of the real

time, continuously corrected

method developed by Parr. No

attempt is made in the Model

6100 Calorimeter to establish

the constant jacket temperature

required for isoperibol calorim-

etry. Instead, the temperature

of the jacket is continuously

monitored and real time heat

leak corrections are applied

based upon the temperature dif-

ference between the bucket and

the actual temperature of the

jacket. While this method is not

truly an isoperibol method, its

real time correction procedure

achieves the same purpose with

nearly equal results. What it can

not do is match the temperature

uniformity of a circulating water

jacket.

Compensated Calorimetry

The Parr 6772 Precision

Thermometer, serving as a

controller for the 1341, 6725

and 6755 Calorimeters, uses

yet another approach to emu-

late the isoperibol calorimetric

method. In these calorimeter

systems, the heat leak is pre-

cisely measured during the

calorimetric pre-period. This

evaluation results in an esti-

mate of the effective, average

temperature of the calorim-

eter surroundings. This tem-

perature value is then used

throughout the test interval to

provide the calorimeter heat

leak correction. While not as

robust as either of the other

two methods outlined above,

it harnesses the computing

power of the controller, with

no additional hardware costs,

to provide heat leak correc-

tion capability that is almost

identical to the approach

used when non-electronic

thermometry and manual

calorimetric techniques are

employed.

P a r r I n s t r u m e n t C o m p a n y

6

w w w . p a r r i n s t . c o m